Custom stencil cutting is a fabrication process used to create precise patterns, shapes, letters, or designs on various materials such as metal, plastic, Mylar, vinyl, cardboard, and stainless steel. Stencils are widely used for branding, painting, signage, labeling, industrial marking, electronics, and decorative applications.

With modern technology, custom stencils can be produced with extremely fine detail and high repeatability.

How Custom Stencil Cutting Works

Custom stencil making typically involves the following steps:

1. Design Preparation

A digital file (AI, DXF, SVG, PDF, etc.) is created with the desired pattern. The design is adjusted to ensure bridges and cut paths are suitable for stencil use.

2. Material Selection

Common materials include:

Mylar (most popular; flexible and durable)

Vinyl

Stainless steel

Aluminum

Plastic sheets

Cardboard/paper for temporary use

3. Cutting Technology

Stencils can be cut using various CNC and digital processes:

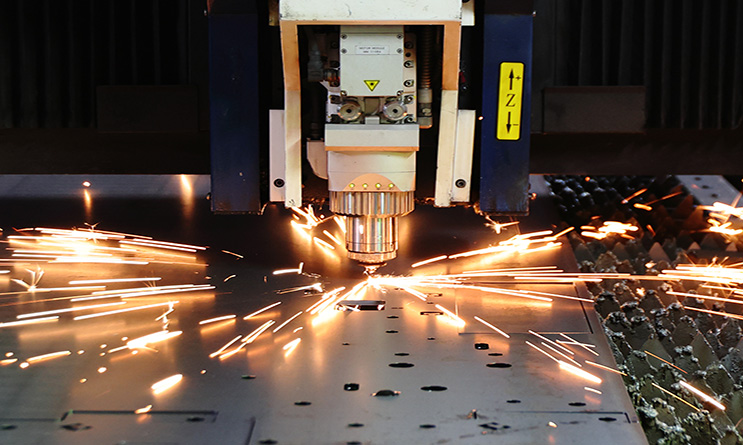

Laser Cutting – extremely precise, ideal for intricate details and small text.

CNC Knife Cutting – good for vinyl and flexible film.

Waterjet Cutting – used for thicker metals without heat distortion.

Plotter Cutting – efficient for large-format lettering and graphics.

4. Finishing

Edges are cleaned, and the stencil may be laminated, reinforced, or fitted with handles depending on customer needs.

Types of Custom Stencil Cutting

Industrial stencils for machinery, crates, containers, and safety labels

Brand stencils for logos, packaging, and product marking

Decorative stencils for art, crafts, room painting, and interior design

Electronic/PCB solder paste stencils (high precision stainless steel)

Automotive marking stencils

Large-format stencils for floors, walls, and signage

Advantages of Custom Stencil Cutting

High precision for detailed designs

Fast production for one-off or bulk orders

Reusable materials such as Mylar and steel improve cost efficiency

Consistent results for branding, marking, and painting

Wide material compatibility for different environments

Supports highly customized designs

Applications of Custom Stencil Cutting

Custom-cut stencils are used across many industries:

Manufacturing & logistics – part numbers, safety labels, crate marking

Construction – floor signs, hazard markings, parking lot numbers

Electronics – solder paste stencils for PCB assembly

Retail & branding – logo and product stencils

Art & design – murals, decorative patterns, hobby projects

Aerospace & automotive – technical labeling and component identification