Metal manufacturing refers to the process of processing, assembling, and manufacturing various components, structures, or products using metal materials such as steel, aluminum, copper, stainless steel, etc. This process can involve multiple process steps, including:

Cutting

Shearing: Straight-line cuts using a shear machine.

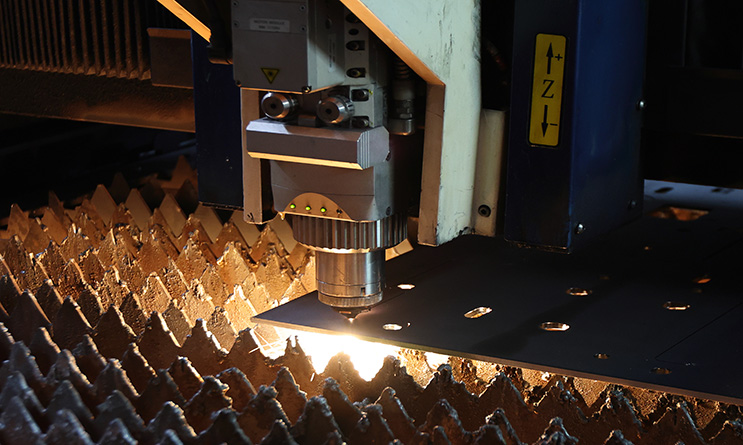

Laser Cutting: Precise, high-speed cutting using a focused laser beam.

Plasma Cutting: Uses a plasma torch to cut conductive materials.

Water Jet Cutting: High-pressure water stream (sometimes with abrasives) for heat-sensitive materials.

Punching: Dies and punches remove shapes from the sheet.

Forming

Bending: Done using press brakes or roll forming machines.

Stamping: Involves pressing the sheet metal into a die.

Deep Drawing: Forms deep, hollow shapes (e.g., cans, tanks).

Spinning: Rotates the metal and forms it over a mandrel.

Joining

Welding: TIG, MIG, spot welding.

Riveting: For permanent mechanical joints.

Fastening: Screws, bolts, and clips.

Adhesive Bonding: For delicate or dissimilar materials.

Finishing

Deburring: Removes sharp edges and burrs.

Polishing and Buffing: For aesthetic or corrosion resistance.

Plating: Adds a surface layer (e.g., zinc, chrome).

Powder Coating or Painting: Protective and aesthetic surface finishes.

Common Materials Used

Steel (Mild, Stainless)

Aluminum

Copper

Brass

Titanium (for aerospace or medical)

Design Considerations

Material thickness (gauge)

Bend radius (minimum to avoid cracking)

Tolerance and clearance (for fitting parts)

Grain direction (important in bending)

Kerf (material lost in cutting)

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, forming a strong joint. There are many types of welding processes, each suited to specific materials, applications, and environments. Here are the major types:

1. Arc Welding Processes

2. Gas Welding Processes

3. Resistance Welding Processes

4. Solid-State Welding Processes

5. Other Specialized Welding Methods

"Machining" refers to a manufacturing process where material is selectively removed from a workpiece to shape it into a desired form. It's commonly used with metals, but also with plastics, composites, and other materials. Machining can involve a variety of techniques.

Common Tools and Equipment

Press brake

CNC laser/plasma cutter

Punch press

Guillotine shear

Rolling machines

Welding setups

Applications

Enclosures and panels

Automotive body parts

HVAC ducts

Aerospace components

Furniture and fixtures

Electronic chassis and brackets

Metal manufacturing is widely used in industries such as construction, automotive, aviation, electronics, and mechanical manufacturing.