The difference between 2D laser cutting and 3D laser cutting

2D laser cutting is a manufacturing process where a laser beam is used to cut flat sheet materials along a two-dimensional path.

How It Works

Material (metal, plastic, wood, composites, etc.) is placed on a flat cutting bed.

A high-powered laser beam (CO₂, fiber, or Nd\:YAG) is directed onto the surface.

The cutting head moves in X and Y directions (two axes) according to the design file (CAD/DXF).

The laser melts, burns, or vaporizes material along the programmed path.

Key Features

Works only on flat materials (no depth contouring).

High precision — tolerances often ±0.1 mm or better.

Can cut intricate patterns, holes, and edges.

Often used with nesting software to minimize material waste.

Can also engrave or etch designs without full cutting.

Common Materials

Mild steel, stainless steel, aluminum

Acrylic, polycarbonate, wood

Thin composites

Advantages

High accuracy for flat parts

Fast production for sheet-based manufacturing

Minimal post-processing

Little or no tool wear (non-contact process)

Limitations

Cannot cut formed or 3D-shaped parts

Limited to thicknesses supported by the laser’s power (e.g., 20–25 mm for steel on high-power machines)

Edge quality may vary with thickness and material type

Example Applications

Sheet metal brackets

Decorative panels and signage

Gaskets

Machine covers and housings

3D laser cutting is a manufacturing process that uses a high-powered laser to cut or trim complex shapes on three-dimensional parts instead of just flat sheets.

How It Works

A multi-axis laser head (often 5-axis or more) moves in X, Y, Z directions and can tilt/rotate to follow curves.

The laser can also be mounted on a robotic arm or paired with a rotating/tilting work table.

The system follows the part’s 3D geometry using a CAD/CAM program, ensuring the cut stays precise even on angled or curved surfaces.

Advantages

Cutting complex shapes:Works on irregular, bent, or formed surfaces.

High precision: Maintains tight tolerances even with intricate contours.

No physical contact:No tool wear; suitable for delicate or thin-walled parts.

Flexibility: Can cut, trim, or drill holes after forming — no need to redesign the part for flat cutting.

Common Applications

Automotive: Trimming car body panels, cutting holes in bumpers, dashboards, or formed sheet metal.

Aerospace: Cutting formed panels, turbine parts, or complex ducts.

Tubes & Pipes: Creating angled cuts, slots, or holes along curved surfaces.

Appliances & Machinery: Modifying pre-formed metal or plastic components.

Typical Machine Types

5-axis CNC laser cutters: Fixed laser source with moving table/head.

Robotic arm laser systems: Laser mounted on a robot for extreme flexibility.

Tube and profile laser cutters: Specialized for round, square, or irregular profiles.

In short:

2D laser cutting stops at flat parts.

3D laser cutting follows the part’s curves — think of it as “laser sculpting” instead of “laser drawing.”

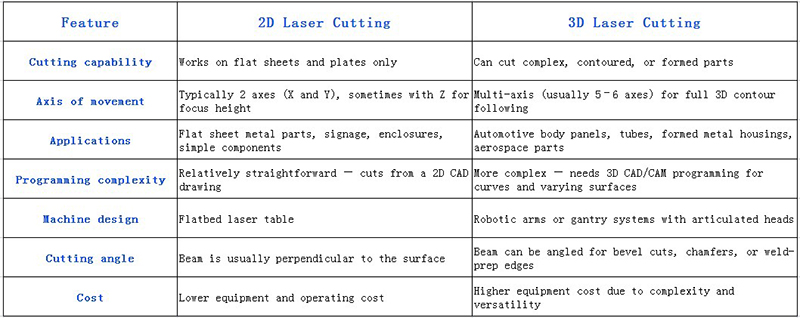

Here’s the key difference between 2D laser cutting and 3D laser cutting, broken down clearly:

1. Cutting Capability & Geometry

2D Laser Cutting

Works on flat sheet materials (metal sheets, plastics, wood, etc.).

Cutting is done in the X and Y axes only.

Can produce flat profiles, holes, and shapes but no contouring along a 3D surface.

Think of it like drawing with a pen on paper — all movement is flat.

3D Laser Cutting

Can cut complex shapes on 3D surfaces (pipes, formed metal parts, car body panels, etc.).

Cutting head moves along X, Y, Z axes and can tilt/rotate to follow curves and angles.

Enables cutting at angles, bevels, and irregular geometries.

Think of it like sculpting — the tool follows the surface in all directions.

2. Equipment Design

2D: Usually a flatbed laser machine with a stationary cutting bed and a gantry system for the laser head.

3D: Often a robotic arm or multi-axis system that can manipulate both the cutting head and/or the workpiece in multiple directions.

3. Typical Applications

2D Laser Cutting:

Sheet metal fabrication

Sign making

Simple enclosures and brackets

3D Laser Cutting:

Automotive parts (e.g., trimming car panels, cutting holes in formed parts)

Aerospace components

Complex tubing and formed metal work

4. Cost & Complexity

2D: Lower cost, faster for flat parts, simpler programming.

3D: More expensive machines, more complex programming (often with CAD/CAM integration), but can handle advanced manufacturing needs.

Quick Analogy

If 2D laser cutting is like cutting cookies from rolled-out dough with a cookie cutter,

then 3D laser cutting is like carving details on a fully baked cake that has hills, slopes, and edges.