Definition of Metal Work Fabrication

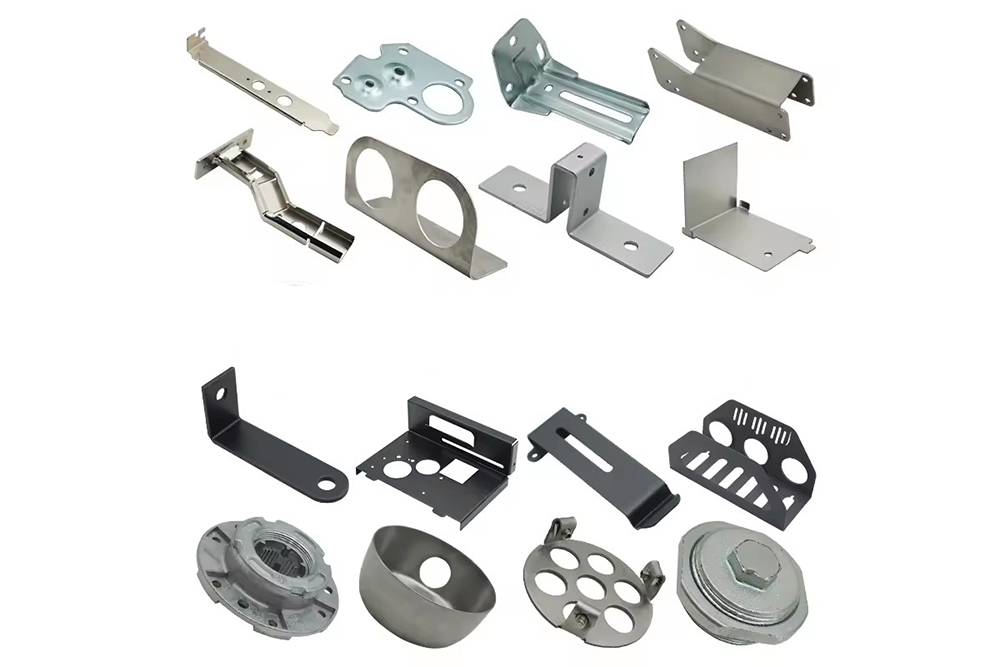

Metal work fabrication refers to the process of cutting, shaping, and assembling raw metal into finished products or structures. Unlike simple machining, which focuses on removing material, fabrication is a broader practice that combines multiple methods such as welding, bending, cutting, and assembling. It serves as the foundation for creating parts, machinery, tools, and structural elements used across construction, automotive, aerospace, energy, and consumer industries.

The fabrication process involves several key steps:

1. Design and Engineering – Using CAD software, engineers create detailed

blueprints with specifications on dimensions, tolerances, and materials.

2. Cutting – Sheets, plates, or bars of metal are cut using methods such as laser

cutting, plasma cutting, or waterjet cutting.

3. Forming and Bending – Metals are reshaped into desired geometries through

press brakes, rolling, or stamping.

4. Welding and Joining – Components are fused together using techniques like

MIG, TIG, or spot welding.

5. Machining and Finishing – Milling, drilling, and grinding refine dimensions and

surfaces.

6. Assembly and Quality Inspection – Final parts are assembled, tested, and

inspected to meet industry standards.

Metal fabrication can be categorized into several main types:

Structural Fabrication – Large-scale projects such as bridges, building frames, and heavy equipment.

Industrial Fabrication – Components for machinery, tools, and production equipment.

Commercial Fabrication – Everyday items such as furniture, appliances, and store fixtures.

Custom Fabrication – Tailored solutions for specialized projects, often involving prototypes or small-batch production.

This classification highlights the adaptability of metal fabrication to projects of any scale.

Services Offered

Custom Design Consultation – Engineers collaborate with clients to optimize product designs.

Prototyping and Testing – Small-scale samples are produced for validation before mass production.

Surface Finishing – Processes like powder coating, painting, galvanizing, or anodizing to improve durability and aesthetics.

Assembly and Packaging – Delivering ready-to-use parts or subassemblies.

Logistics and Supply Chain Support – Coordinating sourcing, inventory, and delivery for large projects.

Such services ensure a complete, end-to-end solution for customers.

Advantages

The popularity of metal fabrication lies in its many benefits:

Versatility – Capable of handling diverse metals such as steel, aluminum, titanium, and copper.

Durability – Fabricated metal products often last longer than those made from alternative materials.

Precision and Consistency – CNC integration guarantees accurate results across large production runs.

Cost Efficiency – Optimized processes reduce waste and minimize production time.

Design Flexibility – Enables the creation of complex and customized structures.

These advantages make metal fabrication indispensable in industries seeking quality and efficiency.

Applications

Construction – Beams, columns, and panels for infrastructure and commercial buildings.

Automotive – Chassis, body panels, exhaust systems, and custom parts.

Aerospace – Lightweight yet strong components for aircraft and spacecraft.

Energy and Utilities – Pipelines, renewable energy equipment, and power plant structures.

Medical and Healthcare – Surgical instruments, hospital equipment, and mobility devices.

Consumer Products – Appliances, furniture, and decorative items.

Its wide-ranging applications underline its role as a backbone of modern life.

Future Outlook

The development prospects for metal work fabrication remain highly positive:

1. Automation and Robotics – Increasing reliance on robotic welding, cutting, and

assembly to improve efficiency.

2. Smart Manufacturing Integration – IoT and AI-driven monitoring systems that

enhance productivity and quality.

3. Sustainability – Growing emphasis on recycling scrap metals, reducing

emissions, and adopting energy-efficient methods.

4. Hybrid Technologies – Combining additive manufacturing with traditional

fabrication to expand design capabilities.

5. Global Market Growth – Rising demand from renewable energy, electric

vehicles, and infrastructure projects worldwide.

Conclusion

Metal work fabrication is more than just bending and welding—it is the foundation upon which industries are built. Defined by its diverse processes, flexible classifications, and expanding services, fabrication ensures that modern society has the structures, machines, and tools it needs to thrive. As technology advances and industries pursue greener, smarter production, metal work fabrication will continue to evolve, shaping not just metal, but the future of global manufacturing.