Sheet metal fabrication refers to the process of transforming flat sheets of metal into various shapes and sizes through techniques such as cutting, bending, punching, welding, and assembling.

It is used in a wide range of industries, including construction, automotive, aerospace, and electronics.

The key steps in sheet metal fabrication typically include:

1.Cutting: The metal sheet is cut to the required size using tools like lasers, water jets, or mechanical shears.

Manual Cutting

Shearing

Laser Cutting (2D/3D)

Plasma Cutting

Water Jet Cutting

Oxy-Fuel Cutting (Flame Cutting)

Punching

CNC Cutting (Computer Numerical Control)

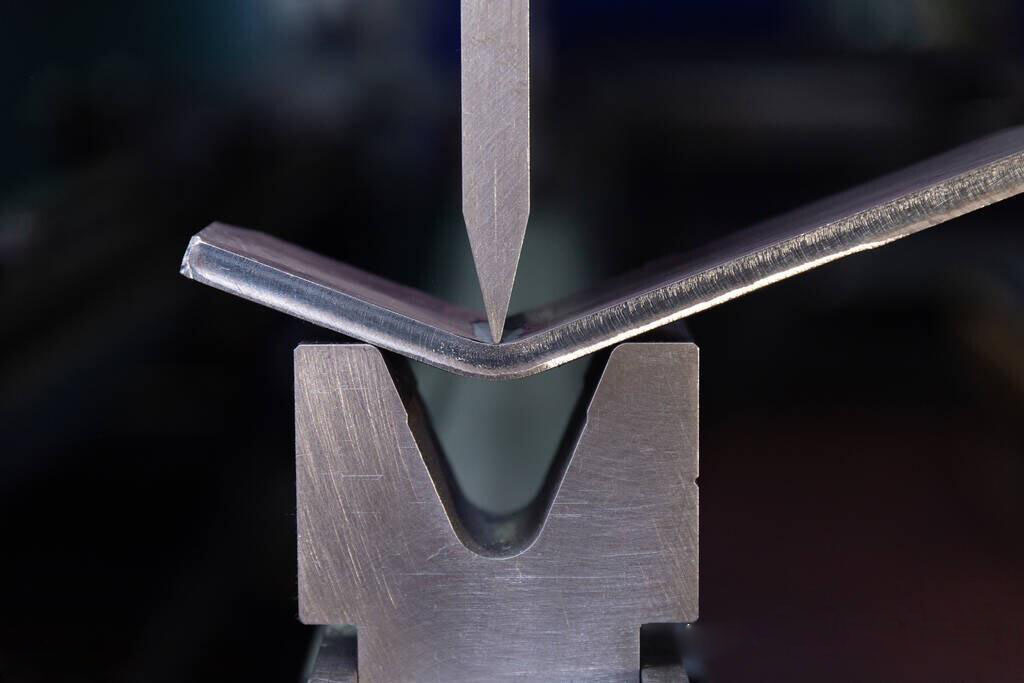

2.Bending: The sheet is bent into specific angles or shapes, often using press brakes or rollers.

Press Brake Bending (V-Bending)

Roll Bending

Rotary Bending

Wipe Bending

U-Bending

Edge Bending (Folding)

Hot Bending

3. Punching/Stamping: Holes and other shapes are punched into the metal using a punch press or laser.

Comparison with Other Cutting Methods

| Method | Speed | Precision | Material Thickness |

|---|---|---|---|

| Punching | Very Fast | Moderate to High | Thin to Medium |

| Laser Cutting | Fast | Very High | Thin to Medium |

| Plasma Cutting | Moderate | Moderate | Medium to Thick |

| Water Jet Cutting | Slow | High | All Thicknesses |

4. Welding: is a fundamental process in metal fabrication used to join two or more metal pieces permanently.

Arc Welding

Resistance Welding

Gas Welding

Solid-State Welding

5. Assembling: Various fabricated parts are assembled into finished products or structures.

Key Methods of Assembling in Sheet Metal Fabrication

Mechanical Fastening

Welding

Adhesive Bonding

Press-Fit Assembly

Snap-Fit Assembly

Folding and Interlocking

Fabricated sheet metal products can be anything from small components like enclosures and brackets to large structures like panels or even intricate parts in machinery and vehicles.