Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

CNC bend factory provide cnc metal tube bending service CNC bending factory made in China Our factory provide cnc tube bending service CNC bending service available CNC Bend OEM Best quality cnc metal bending

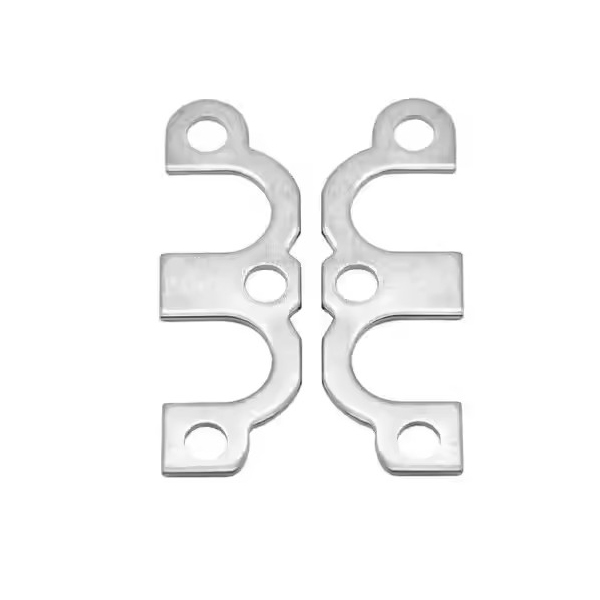

Provide OEM ODM service for metal stamping,stainless steel stamping. Our factory has over 25 years of experience in precision sheet metal stamping. High volume metal stamping with factory price. High precision metal stamping made in China.

Custom Sheet Metal Aluminium Fabrication

Aluminium fabrication refers to the process of shaping, cutting, and forming aluminium into finished products or parts. It involves various techniques such as welding, bending, machining, and assembling aluminium sheets, extrusions, and castings to create structures or components for different applications.

Aluminium sheet metal fabrication involves the process of transforming flat aluminium sheets into various shapes and structures through cutting, bending, forming, and assembling techniques.

Cutting: Aluminium can be cut using saws, lasers, or water jets, depending on the thickness and precision required.

Forming: This includes bending and shaping aluminium into desired shapes using machines like press brakes or rollers.

Welding: Aluminium welding techniques include TIG (tungsten inert gas), MIG (metal inert gas), and resistance welding, which are chosen based on the thickness and specific requirements of the aluminium components.

Machining: Machining processes like drilling, milling, and turning are used to create precise holes, slots, and surface finishes on aluminium parts.

Assembly: Aluminium parts are often assembled using fasteners, adhesives, or welding, depending on the structural and functional requirements.

Finishing: Surface treatments such as anodizing, painting, or powder coating are applied to protect aluminium from corrosion or to enhance its appearance.

Aluminum sheet metal fabrication involves the process of shaping and transforming aluminum sheets into various products or components through various methods such as cutting, bending, welding, punching, and assembling.This process is widely used in industries like automotive, aerospace, construction, and electronics.

Here’s a brief overview of key processes in aluminum sheet metal fabrication:

1. Bending

Press Brake Bending: A press brake is used to apply force to the aluminum sheet to bend it at precise angles.This is often used to create U, L, or V shapes.

Roll Bending: Involves passing the sheet through a series of rollers to bend it into curves or cylindrical shapes.

2 .Punching & Stamping

Punching: Uses a punch press to create holes or cutouts in aluminum sheets.

Punching is ideal for repetitive tasks and high-volume production.

Stamping: A more complex form of punching, where multiple shapes are stamped into the material, often used for creating parts with specific patterns.

Applications of Aluminum Sheet Metal Fabrication

Automotive: Used for body panels, engine components, and trim.

Aerospace: Aircraft components like wings, fuselage parts, and structural elements.

Construction: Roofing, cladding, window frames, and decorative elements.

Electronics: Housings, enclosures, and cooling components for devices.

Aluminium fabrication is widely used in industries such as aerospace, automotive, construction, and electronics due to aluminium's lightweight nature, corrosion resistance, and strength-to-weight ratio. The process requires expertise in metallurgy, engineering design, and manufacturing techniques to achieve high-quality, durable aluminium products.

Do you have a specific project or technique in mind? I can give more detailed advice depending on what you're looking for!