Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

CNC bend factory provide cnc metal tube bending service CNC bending factory made in China Our factory provide cnc tube bending service CNC bending service available CNC Bend OEM Best quality cnc metal bending

Provide OEM ODM service for metal stamping,stainless steel stamping. Our factory has over 25 years of experience in precision sheet metal stamping. High volume metal stamping with factory price. High precision metal stamping made in China.

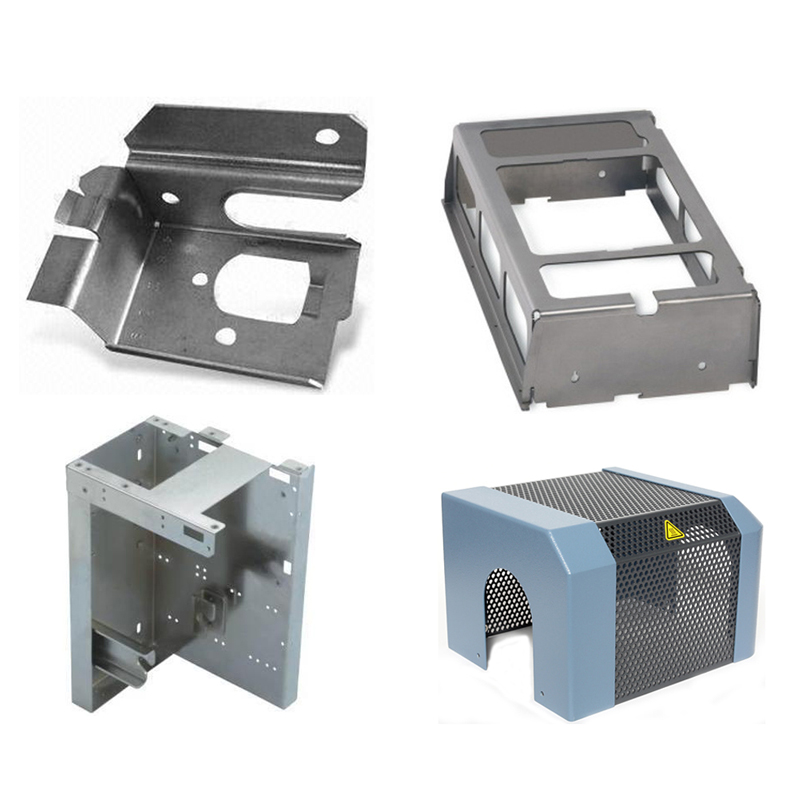

Custom Stainless Steel Sheet Metal Fabrication

Stainless steel fabrication,one type of sheet metal fabrication involves the process of cutting, shaping, and assembling stainless steel components to create various products.

Design and Planning: The process begins with designing the product based on customer requirements and specifications. This involves determining dimensions, tolerances, and material requirements.

Material Selection: Stainless steel is chosen for its corrosion resistance, strength, and aesthetic appeal. Different grades of stainless steel (e.g., 304, 316) may be selected based on the application's requirements.

Cutting: Stainless steel sheets or bars are cut to size using various methods such as shearing, sawing, laser cutting, or plasma cutting. Precision is crucial to achieve the desired dimensions.

Forming: Stainless steel can be formed into different shapes using techniques like bending, rolling, or stamping. This step shapes the material into the required geometry.

Welding: Stainless steel parts are often welded together using techniques such as TIG (Tungsten Inert Gas) welding or MIG (Metal Inert Gas) welding. This joins the pieces securely while maintaining the material's corrosion resistance.

Finishing: After fabrication, stainless steel components may undergo finishing processes such as grinding, polishing, or bead blasting to improve surface smoothness, remove imperfections, and enhance aesthetics.

Assembly: Components are assembled into the final product, which may involve mechanical fastening, adhesives, or further welding.

Quality Control: Throughout the fabrication process, quality control measures ensure that each component meets specified tolerances, dimensions, and surface finish requirements. This includes inspections, measurements, and testing.

Stainless steel fabrication involves cutting, shaping, and assembling stainless steel materials into desired forms or products. This process is widely used across industries such as construction, automotive, food processing, and manufacturing due to the material’s durability, resistance to corrosion, and sleek finish.

Stainless steel fabrication is utilized in various industries including automotive, aerospace, construction, food processing, and healthcare due to its durability, hygiene properties, and aesthetic appeal.

We are a professional sheet metal fabrication factory with advanced production lines and strong research and development capabilities.

We welcome your inquiries at any time.