Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

CNC bend factory provide cnc metal tube bending service CNC bending factory made in China Our factory provide cnc tube bending service CNC bending service available CNC Bend OEM Best quality cnc metal bending

Provide OEM ODM service for metal stamping,stainless steel stamping. Our factory has over 25 years of experience in precision sheet metal stamping. High volume metal stamping with factory price. High precision metal stamping made in China.

Medical Oem Metal Small Brass Stampingn Parts

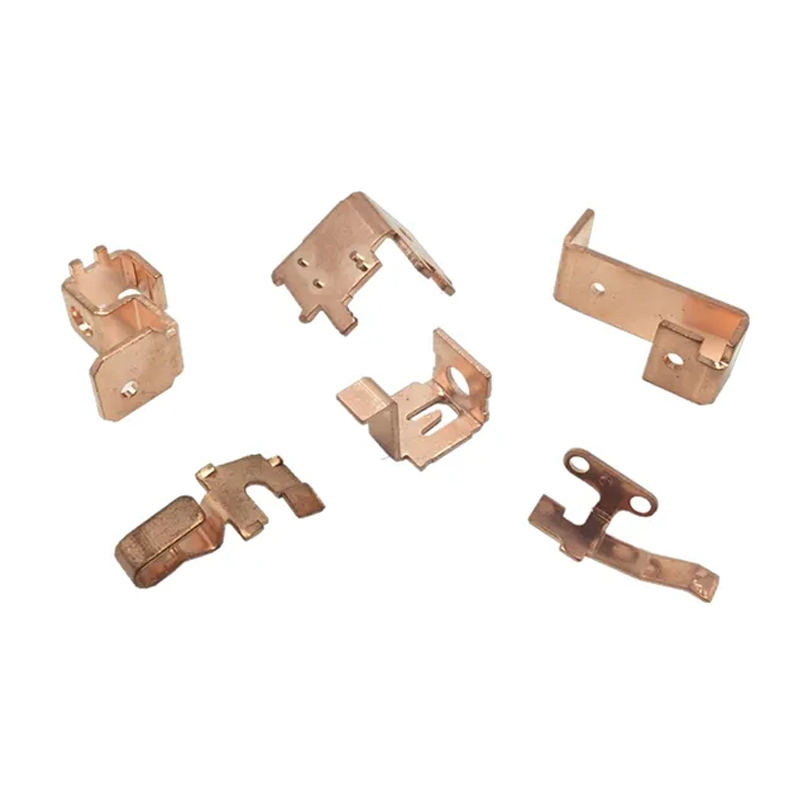

Brass stamping parts typically refer to components made from brass using the stamping process. Stamping is a manufacturing process where flat sheet metal is pressed into a specific shape using a stamping die and a mechanical or hydraulic press. Brass, a metal alloy of copper and zinc, is favored for stamping parts due to its corrosion resistance, durability, and attractive appearance. oem stamping parts include:

Electronic components: Brass stampings are used in various electrical and electronic applications, such as connectors, terminals, and shielding components.

Hardware: They are utilized in hardware products like hinges, latches, handles, and decorative elements due to brass's aesthetic appeal and strength.

Automotive parts: Brass stampings find applications in the automotive industry for components like brackets, clips, and terminals due to their strength and resistance to wear.

Medical metal stamping is a manufacturing process used to produce precision parts and components for the medical industry. It involves shaping and cutting metal sheets (typically from stainless steel, titanium, or other biocompatible materials) into specific forms using high-pressure stamping tools and dies. This process is commonly used for creating items like surgical instruments, implants, diagnostic equipment, and other medical devices that require high accuracy and reliability.

Key aspects of medical metal stamping include:

1. Precision & Quality: Medical components often have strict tolerances and require high-quality finishes. The stamping process can produce complex geometries with tight tolerances, ensuring the functionality and safety of the final product.

2. Materials: Medical devices often require materials that are biocompatible and resistant to corrosion. Stainless steel, titanium, and certain alloys are frequently used due to their durability and non-reactive nature in the human body.

3. Customization: The medical industry frequently requires custom-designed parts, so stamping dies can be tailored to produce a wide variety of shapes, sizes, and configurations, such as perforated sheets, brackets, and housing components.

4. High Volume Production: Metal stamping is well-suited for high-volume manufacturing, making it cost-effective for mass production of medical components. Once a die is created, the process can quickly produce large quantities of parts with minimal variation.

5. Cleanliness & Sterility: Given the nature of the medical industry, it's crucial that the stamping process and the finished parts meet strict cleanliness and sterility standards. Manufacturing environments may include clean rooms or additional post-processing steps to ensure components are free of contaminants.

6. Regulatory Compliance: Medical metal stamping is subject to strict regulatory standards, such as the FDA’s regulations for medical devices (21 CFR Part 820), ISO 13485 (quality management systems for medical devices), and ISO 10993 (biological evaluation of medical devices).

Common applications of medical metal stamping include:

Surgical Instruments: Scalpels, forceps, tweezers, and other surgical tools.

Implants: Spinal implants, dental implants, orthopedic devices, and other body implants.

Diagnostic Equipment: Components for devices like blood analyzers or ECG machines.

Orthopedic Components: Plates, screws, and brackets used in bone fracture repair.

We iffer OEM so many stamping service include:metal stamping small parts, oem stamping parts, oem metal stamping parts, medical metal stamping.