Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

CNC bend factory provide cnc metal tube bending service CNC bending factory made in China Our factory provide cnc tube bending service CNC bending service available CNC Bend OEM Best quality cnc metal bending

Provide OEM ODM service for metal stamping,stainless steel stamping. Our factory has over 25 years of experience in precision sheet metal stamping. High volume metal stamping with factory price. High precision metal stamping made in China.

Metal Stamping Parts Factory

Metal stamping parts are components manufactured through the process of metal stamping, which involves pressing or punching a metal sheet or coil with a mechanical or hydraulic press to create the desired shape. This process is widely used in various industries due to its ability to produce parts with high precision and repeatability at a relatively low cost.

Processes: The process typically involves several stages:

Blanking: Cutting the flat sheet of metal into a specific shape (blank).

Forming: Bending or shaping the metal into the desired 3D form.

Piercing: Creating holes or cutouts in the metal.

Coining: Pressing fine details into the part.

Drawing: Shaping the metal into deep, cup-like shapes.

Embossing/Etching: Creating patterns or designs on the surface.

Tooling: Metal stamping requires specialized tooling, including dies and punches, which are designed based on the part's geometry and material thickness. Tooling costs can be significant but are amortized over large production runs.

Materials:

Steel: Common for strength and durability.

Aluminum: Lightweight and corrosion-resistant.

Brass: Used for electrical and decorative parts.

Copper: Known for good conductivity.

Stainless Steel: For parts requiring resistance to rust and corrosion.

Quality Control: Inspection and quality assurance processes are crucial to ensure parts meet specifications. Techniques include visual inspection, dimensional measurement, and material testing.

Common Types of Metal Stamping Parts:

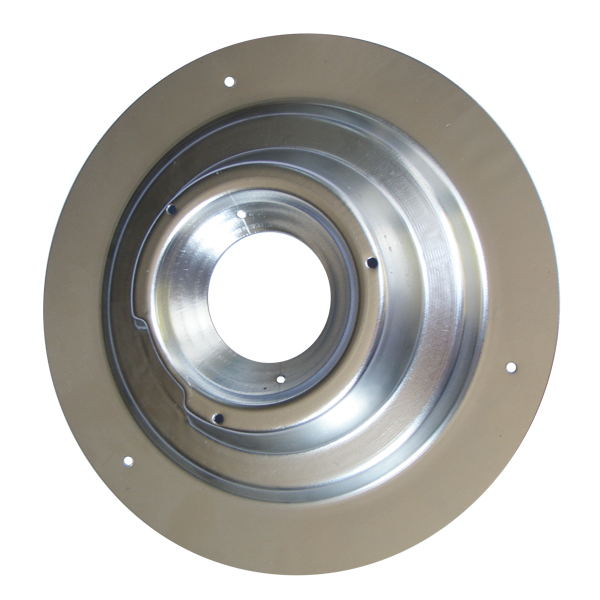

Automotive Parts: Door panels, chassis, bumpers, brackets, and engine components.

Electronics: Enclosures, connectors, brackets, and heat sinks.

Appliances: Housing, brackets, handles, and trim parts.

Industrial: Tooling parts, frames, and machinery components.

Consumer Products: Components like cookware, furniture hardware, and decorative items.

Advantages:

High Precision: The process can achieve tight tolerances.

Mass Production: Stamping is cost-effective for producing large quantities.

Strength: Metal parts are often stronger than plastic counterparts.

Efficiency: Fast and repeatable production.

Automotive Industry: Metal stamping is crucial for making lightweight but strong parts like fenders, engine components, and transmission parts.

Electronics Industry: Produces connectors, battery housings, and other components.

Home Appliances: Creates durable, high-quality parts like brackets and casings.

Overall, metal stamping is a versatile manufacturing process that plays a crucial role in producing a wide range of metal parts used in everyday products and industrial applications.

We are metal stamping parts factory with 25years experience,please send us your design drawings.