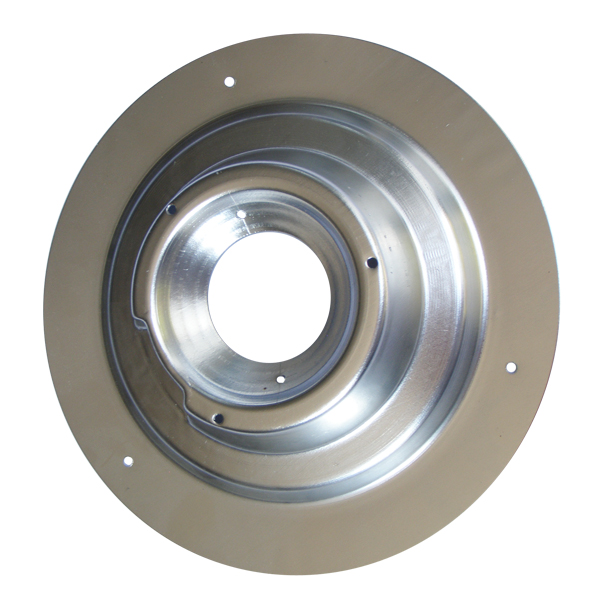

Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

CNC bend factory provide cnc metal tube bending service CNC bending factory made in China Our factory provide cnc tube bending service CNC bending service available CNC Bend OEM Best quality cnc metal bending

Provide OEM ODM service for metal stamping,stainless steel stamping. Our factory has over 25 years of experience in precision sheet metal stamping. High volume metal stamping with factory price. High precision metal stamping made in China.

Precision Metal Titanium Aluminum Sheet Stamping

Precision metal stamping is a manufacturing process used to create parts and components from sheet metal. It involves feeding flat sheet metal into a stamping press where a tool and die set forms the metal into the desired shape. This process is highly automated and precise, capable of producing complex geometries with tight tolerances. Precision metal stamping includes but is not limited to aluminum stamping, stamping aluminum sheet, titanium stamping.

Tool and Die: The tool and die set consists of a punch (which pushes the metal into the die), the die (which shapes the metal), and possibly other components like strippers and holders.

Materials: Typically uses sheet metal materials such as steel, aluminum, brass, copper, and sometimes exotic metals depending on the application's requirements.

Precision and Tolerances: Offers high precision and repeatability, making it suitable for mass production of parts with tight tolerances.

Automation: Often automated with progressive or transfer stamping systems, reducing labor costs and increasing production efficiency.

Applications: Widely used across industries including automotive, aerospace, electronics, telecommunications, and more, where high-volume production of precise metal parts is needed.

Advantages: Provides cost-effective production of complex parts, fast cycle times, and consistency in part quality.

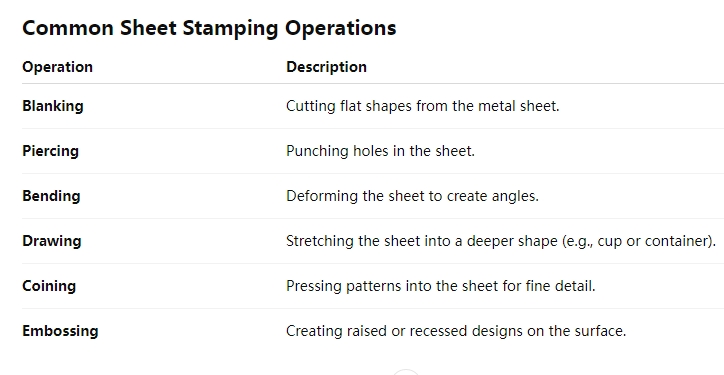

Sheet stamping is a manufacturing process used to shape flat metal sheets into specific forms using dies and presses. It is widely used in industries like automotive, aerospace, appliances, and electronics for making parts such as car body panels, brackets, enclosures, and more.

Key Elements of Sheet Stamping

Material:

Typically uses thin metal sheets such as steel, aluminum, copper, or alloys.

Sheet thickness can vary depending on the application.

Dies:

Tools that define the shape of the stamped part.

Comprised of two parts: punch (upper tool) and die (lower tool).

Press:

The machine that applies pressure to the punch to shape the sheet.

Types include mechanical, hydraulic, and servo presses.

Advantages of Sheet Stamping

High production rates

Low per-unit cost at scale

Consistency and repeatability

Good dimensional accuracy

Disadvantages

High tooling cost for dies

Limited to thin sheet materials

Tool wear and maintenance required

Overall, precision metal stamping is crucial in modern manufacturing for creating a wide range of parts that are essential in various industries due to its efficiency, precision, and capability to handle high-volume production needs.