Sheet Metal Fabrication: A Core Manufacturing Solution for Modern Industries

In today’s industrial landscape, sheet metal fabrication plays a vital role in transforming flat metal sheets into functional, high-precision components used across countless industries. From simple brackets to complex enclosures and structural assemblies, sheet metal fabrication combines advanced technology, skilled craftsmanship, and efficient production methods. This blog provides a comprehensive overview of what sheet metal fabrication is, how it works, its main process types, service scope, advantages, and practical applications.

What Is Sheet Metal Fabrication?

Sheet metal fabrication is a manufacturing process that involves cutting, forming, bending, joining, and finishing metal sheets to create custom parts or assemblies. Commonly used metals include stainless steel, carbon steel, aluminum, copper, brass, and galvanized steel. The process supports both prototype development and high-volume production, making it a flexible solution for a wide range of industrial needs.

Sheet metal fabrication is valued for its precision, repeatability, material efficiency, and ability to produce complex geometries with consistent quality.

Sheet Metal Fabrication Process

The fabrication process typically follows several structured steps:

1. Design and Engineering

Parts are designed using CAD software, ensuring dimensional accuracy and manufacturability.

2. Cutting

Metal sheets are cut to shape using laser cutting, plasma cutting, water jet cutting, or mechanical shearing.

3. Forming and Bending

Press brakes, rolling machines, and stamping tools are used to bend or shape metal sheets into the desired geometry.

4. Joining and Assembly

Components are joined through welding, riveting, fastening, or clinching.

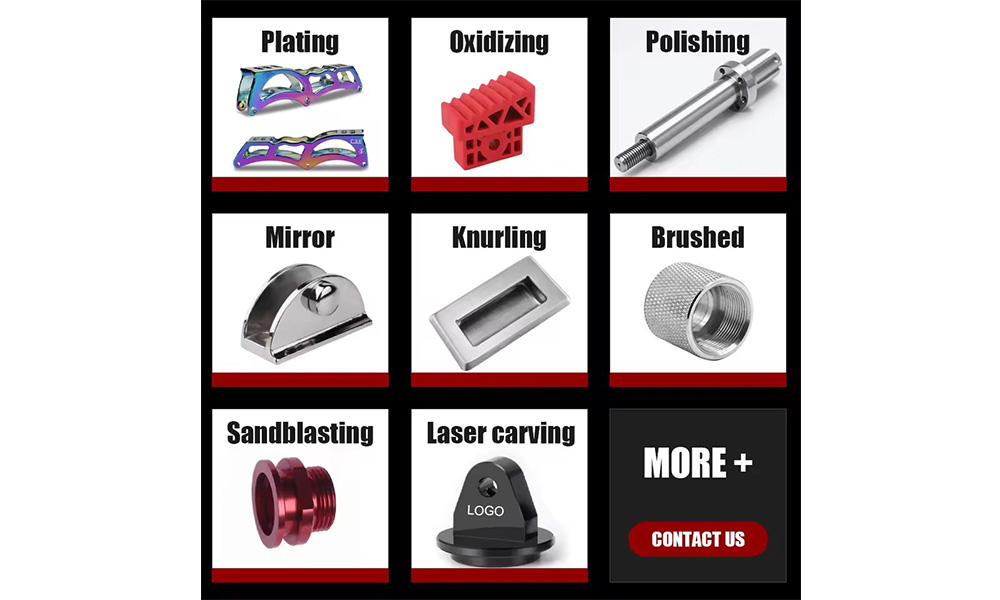

5. Surface Finishing

Finishes such as polishing, powder coating, electroplating, electrophoresis, or painting are applied to enhance appearance and performance.

6. Inspection and Packaging

Finished parts are inspected for quality and prepared for delivery.

Each step is carefully controlled to ensure consistency and compliance with customer specifications.

Types of Sheet Metal Fabrication

Sheet metal fabrication can be classified based on processing methods and complexity:

Cut-to-Shape Fabrication – Simple flat components

Bending and Forming Fabrication – Brackets, panels, and enclosures

Stamping and Press Forming – High-volume parts with tight tolerances

Welded Fabrication – Structural frames and assemblies

Precision Sheet Metal Fabrication – Tight tolerances for electronics and medical devices

Custom Fabrication – Low-volume or specialized components

Each type is selected based on material, design complexity, and production volume.

Sheet Metal Fabrication Services

Professional sheet metal fabrication services typically include:

CAD/CAM engineering support

Laser and CNC cutting

CNC bending and forming

Welding and assembly

Surface finishing and coating

Prototype and mass production

Quality inspection and testing

One-stop manufacturing solutions

Integrated services help reduce lead times, control costs, and ensure consistent quality.

Advantages of Sheet Metal Fabrication

Sheet metal fabrication offers several key benefits:

High precision and repeatability

Cost-effective for both low and high volumes

Excellent strength-to-weight ratio

Wide material and thickness range

Design flexibility and customization

Scalable production capacity

Compatibility with automation

These advantages make sheet metal fabrication a preferred manufacturing method across industries.

Applications of Sheet Metal Fabrication

Sheet metal fabrication is widely used in:

Automotive – brackets, frames, body components

Electronics – enclosures, cabinets, chassis

Industrial machinery – housings, guards, structural parts

Construction – panels, supports, architectural elements

Medical equipment – precision housings and components

Energy and electrical – control boxes, cabinets, mounts

Consumer products – appliances, furniture, hardware

Its versatility allows manufacturers to meet diverse functional and aesthetic requirements.

Conclusion

As industries continue to demand higher precision, faster delivery, and reliable quality, sheet metal fabrication remains a cornerstone of modern manufacturing. By combining advanced machinery, skilled engineering, and comprehensive services, sheet metal fabrication enables the efficient production of durable, high-quality components. Choosing an experienced fabrication partner ensures optimized designs, consistent results, and long-term value for any project.