Laser Cutting and Bending: An Integrated Solution for Precision Metal Fabrication

In modern manufacturing, speed, precision, and flexibility are essential to meet growing demands for high-quality metal components. Laser cutting and bending has emerged as a highly efficient and reliable fabrication solution, combining advanced laser technology with CNC-controlled forming processes. This integrated approach enables manufacturers to produce complex sheet metal parts with excellent accuracy, consistent quality, and reduced lead times. This blog explores what laser cutting and bending is, how the process works, its main classifications, service offerings, advantages, and wide-ranging applications.

What Is Laser Cutting and Bending?

Laser cutting and bending refers to a manufacturing process in which flat metal sheets are first cut into precise shapes using laser technology and then formed into three-dimensional parts through CNC bending or press brake operations. Laser cutting ensures clean edges and accurate profiles, while bending transforms the cut parts into functional components with precise angles and dimensions.

This combination is widely used in sheet metal fabrication for both prototype development and mass production.

Laser Cutting and Bending Process

The integrated process typically includes the following steps:

1. Design and Engineering

Parts are designed using CAD software, with bending allowances and tolerances carefully calculated.

2. Laser Cutting

CNC laser cutting machines cut metal sheets according to programmed designs. This process delivers high precision, minimal material waste, and smooth edges.

3. Deburring and Inspection

Cut parts may undergo deburring or edge finishing to ensure safety and surface quality.

4. CNC Bending

CNC press brakes or automatic bending machines form the parts into the required shapes with precise angles and repeatability.

5. Secondary Processing

Welding, tapping, surface finishing, or assembly may follow, depending on application requirements.

6. Final Inspection and Packaging

Dimensional checks ensure conformity before delivery.

This streamlined workflow enhances efficiency and product consistency.

Types of Laser Cutting and Bending

Laser cutting and bending services can be classified based on materials, complexity, and production scale:

2D Laser Cutting and Bending – Flat sheet cutting followed by standard bending

Precision Laser Cutting and CNC Bending – Tight tolerances and complex geometries

Prototype and Small-Batch Fabrication – Fast turnaround for development projects

High-Volume Production – Automated cutting and bending for mass manufacturing

Custom Laser Cutting and Bending – Tailored solutions for unique designs

Thick and Thin Sheet Processing – Covers a wide range of material thicknesses

Each type addresses specific manufacturing needs.

Laser Cutting and Bending Services

Professional service providers typically offer:

CAD/CAM engineering support

Fiber or CO₂ laser cutting for various metals

CNC press brake bending and forming

Material selection assistance

Secondary operations such as welding and finishing

Prototype to mass production capabilities

Quality inspection and documentation

One-stop laser cutting and bending services help reduce coordination costs and production lead times.

Advantages of Laser Cutting and Bending

This combined fabrication method offers numerous benefits:

High dimensional accuracy and repeatability

Clean edges with minimal post-processing

Efficient material utilization and reduced waste

Fast production cycles

Flexibility for complex and custom designs

Cost-effectiveness for both low and high volumes

Compatibility with automation and smart manufacturing

These advantages make laser cutting and bending a preferred choice in modern metal fabrication.

Applications of Laser Cutting and Bending

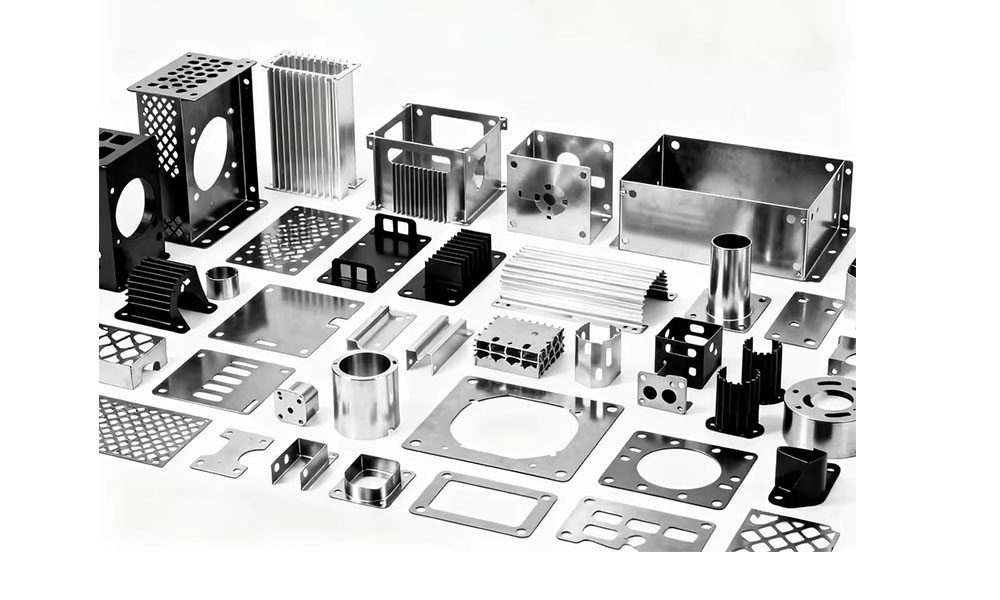

Laser cutting and bending is widely applied across industries such as:

Automotive – brackets, frames, structural components

Electronics – enclosures, cabinets, chassis

Industrial machinery – guards, housings, panels

Construction and architecture – metal panels, supports, decorative elements

Energy and electrical – control boxes, mounting brackets

Medical and laboratory equipment – precision housings

Furniture and consumer products – metal frames and customized parts

Its versatility supports both functional and aesthetic requirements.

Conclusion

As manufacturers seek faster production, higher precision, and greater design flexibility, laser cutting and bending continues to gain importance as a core fabrication solution. By combining accurate laser cutting with reliable CNC bending, this integrated process delivers high-quality metal components with efficiency and consistency. Choosing an experienced laser cutting and bending service provider ensures optimized designs, reliable production, and long-term value for any fabrication project.