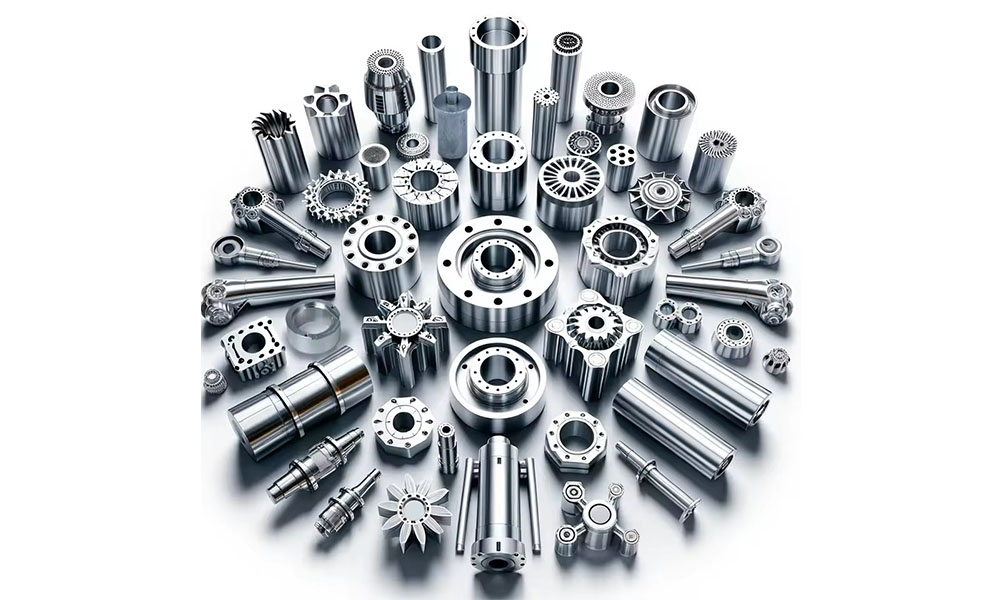

Precision Metal Fabrication: Delivering Accuracy and Reliability in Advanced Manufacturing

As manufacturing industries continue to evolve toward higher quality and tighter tolerances, precision metal fabrication has become an essential solution for producing complex, high-performance metal components. From critical industrial parts to sophisticated enclosures and assemblies, precision metal fabrication combines advanced technology, engineering expertise, and strict quality control to meet demanding specifications. This blog explores what precision metal fabrication is, how it works, its main processes, service scope, advantages, and industrial applications.

What Is Precision Metal Fabrication?

Precision metal fabrication refers to the process of manufacturing metal parts and assemblies with extremely tight tolerances, high dimensional accuracy, and consistent quality. Unlike standard fabrication, precision fabrication focuses on detailed engineering, controlled processes, and advanced equipment to ensure every component meets exact design requirements.

This manufacturing method is commonly applied to stainless steel, aluminum, carbon steel, copper, brass, and other specialty alloys, supporting both prototype development and large-scale production.

Precision Metal Fabrication Process

The precision metal fabrication workflow involves multiple carefully controlled steps:

1. Design and Engineering

CAD and CAM software are used to optimize part design, tolerances, and manufacturability before production begins.

2. Cutting and Machining

Laser cutting, CNC punching, water jet cutting, and CNC machining are employed to achieve high-accuracy profiles and features.

3. Forming and Bending

CNC press brakes and forming equipment shape metal sheets with precise angles and repeatability.

4. Welding and Assembly

TIG, MIG, laser welding, and robotic welding ensure strong joints while maintaining dimensional accuracy.

5. Surface Finishing

Processes such as polishing, powder coating, anodizing, electroplating, and electrophoresis enhance surface quality and performance.

6. Inspection and Quality Control

Dimensional inspection, surface measurement, and functional testing verify compliance with specifications.

Each stage is integrated to maintain precision from raw material to final product.

Types of Precision Metal Fabrication

Precision metal fabrication can be classified by production method and application:

Precision Sheet Metal Fabrication – Thin-gauge components with tight tolerances

CNC Machined Fabrication – High-accuracy parts requiring milling or turning

Welded Precision Assemblies – Complex structures requiring strict dimensional control

Prototype and Low-Volume Fabrication – Design validation and product development

High-Volume Precision Production – Consistent, repeatable manufacturing for mass production

Custom Precision Fabrication – Specialized parts designed for unique applications

Each type serves different functional and performance requirements.

Precision Metal Fabrication Services

Professional fabrication providers typically offer comprehensive services, including:

Engineering and design support

CNC laser cutting and machining

CNC bending and forming

Precision welding and assembly

Surface finishing and coating

Prototype development and scaling to mass production

Dimensional inspection and quality assurance

One-stop manufacturing solutions

These services streamline production and reduce lead times while ensuring high-quality output.

Advantages of Precision Metal Fabrication

Precision metal fabrication offers several key advantages:

Exceptional dimensional accuracy

Consistent quality and repeatability

Ability to handle complex designs

Wide material and thickness range

Reduced material waste

Improved product performance and reliability

Cost efficiency over the product lifecycle

These benefits make precision fabrication ideal for demanding industrial environments.

Applications of Precision Metal Fabrication

Precision metal fabrication is widely used across industries such as:

Automotive – structural components, brackets, housings

Aerospace – lightweight, high-strength parts

Electronics – enclosures, chassis, heat management components

Medical devices – precision housings and instrument components

Industrial machinery – high-accuracy frames and functional parts

Energy and electrical – control cabinets, mounting systems

Telecommunications – racks and structural components

In each application, precision fabrication ensures performance, safety, and durability.

Conclusion

As product requirements become more complex and performance-driven, precision metal fabrication continues to play a critical role in modern manufacturing. By combining advanced equipment, skilled engineering, and rigorous quality control, precision fabrication delivers reliable, high-quality metal components tailored to exact specifications. Partnering with an experienced precision metal fabrication provider helps manufacturers achieve efficiency, consistency, and long-term success.