Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

CNC bend factory provide cnc metal tube bending service CNC bending factory made in China Our factory provide cnc tube bending service CNC bending service available CNC Bend OEM Best quality cnc metal bending

Provide OEM ODM service for metal stamping,stainless steel stamping. Our factory has over 25 years of experience in precision sheet metal stamping. High volume metal stamping with factory price. High precision metal stamping made in China.

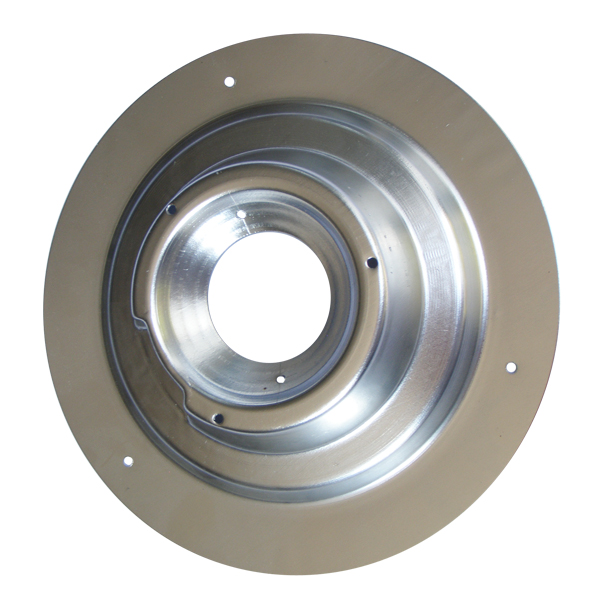

Custom Wholesale Metal Aluminum Stamping Parts

Stamping aluminum parts,also know as aluminium stamping parts ,one of the metal stamping parts,typically involves a manufacturing process where a sheet of aluminum is formed into a desired shape and size using a stamping press and dies.

Material Selection: Choose the appropriate grade and thickness of aluminum sheet based on the requirements of the part (e.g., 1000 series, 5000 series, etc.).

Die Design: Design or procure dies that define the shape of the part to be stamped. Dies are usually made from hardened tool steel and consist of a male (punch) and female (die) component.

Stamping Process:

- The press applies force to the punch, which forces the aluminum sheet into the die cavity.

- This action shapes the aluminum into the desired form, which could be a simple shape like a flat washer or a more complex part with bends and contours.

Setup: Set up the stamping press with the appropriate dies and ensure the sheet of aluminum is securely held in place.

Trimming and Finishing:

- After stamping, excess material (flash) may need to be trimmed off to achieve the final shape.

- Additional finishing processes such as deburring, cleaning, and surface treatment (anodizing, painting, etc.) may be applied depending on the application requirements.

Key Considerations:

- Material Properties: Aluminum’s properties (such as ductility and strength) influence how it behaves during stamping.

- Die Maintenance: Regular maintenance of dies is crucial for consistent quality and longevity.

- Production Efficiency: Optimizing stamping parameters (like press speed and pressure) can improve efficiency and reduce costs.

Stamping aluminum parts is a process commonly used in manufacturing, where sheets of aluminum are fed into a press, and a tool (called a die) shapes or cuts them into the desired form. This process can involve bending, punching, blanking, or other techniques depending on the desired outcome. It’s widely used in industries like automotive, aerospace, electronics, and appliance manufacturing because aluminum is lightweight, durable, and corrosion-resistant.

Some key factors to consider when stamping aluminum parts:

Material Thickness: Aluminum can be stamped in various thicknesses. Thicker materials require more force and more robust dies.

Die Design: The design of the stamping die is critical for precision and quality. It must be tailored to the part's geometry and production volume.

Lubrication: Aluminum can have a tendency to stick to the die, so using a lubricant is essential to reduce wear on the die and ensure smooth material flow.

Tensile Strength of Aluminum: While aluminum is a relatively soft metal, it still has varying tensile strengths depending on the alloy. The choice of alloy (like 3003, 5052, or 6061) influences the ease of stamping and the properties of the final part.

Cycle Time: Stamping operations can be highly automated, and cycle time (the time it takes to complete one stamp) is a key factor in determining production rates.

Part Complexity: Complex parts may require multiple stages of stamping or intricate die designs. More intricate designs could lead to higher costs or difficulty in achieving desired tolerances.

Overall, stamping is a cost-effective method for producing high volumes of aluminum parts with consistent quality and dimensional accuracy, making it suitable for various industries including automotive, aerospace, and consumer electronics.