Precision Stamping Die Services: From Design to Validation

We provide comprehensive stamping die design and manufacturing services, ensuring high-quality metal parts production.

1. Expert Die Design*

Our engineering team utilizes advanced CAD/CAE software to create optimal die designs. We focus on strip layout optimization, material selection and forming simulation to prevent defects and ensure production efficiency. Our designs accommodate single-stage, compound and progressive die configurations based on your requirements.

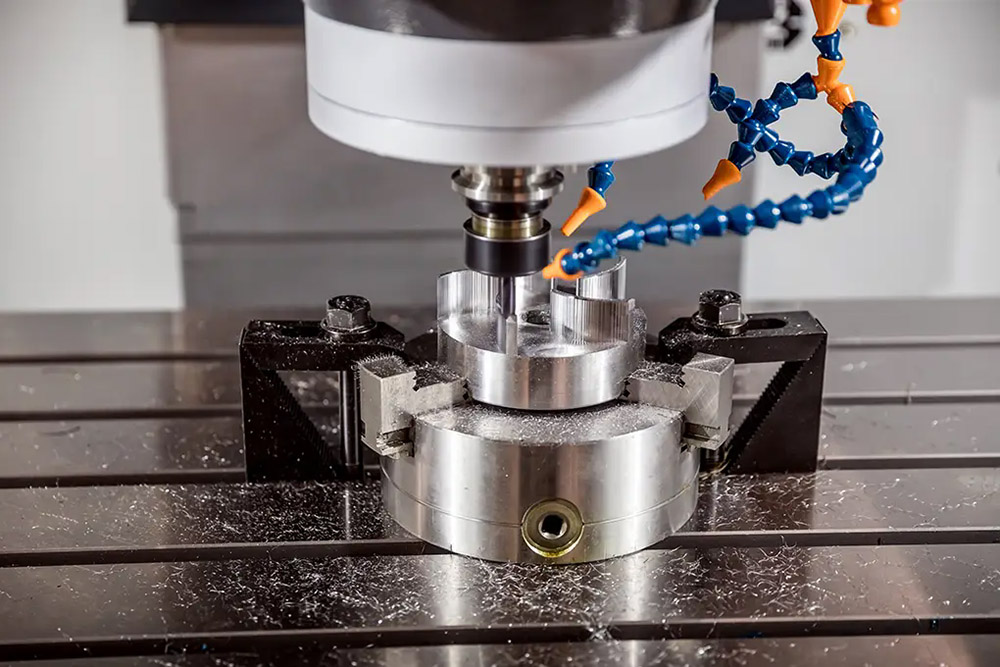

2. Precision Manufacturing

We employ state-of-the-art CNC machining centers, wire-cut EDMs and grinding equipment to manufacture die components with micron-level accuracy. Our workshop processes various tool steels and carbides, maintaining strict quality control throughout production.

3. Surface Treatment

We apply specialized treatments to enhance die performance and longevity. Our services include:

Precision polishing for smooth material flow

Heat treatment for improved hardness

PVD coatings (TiN, TiCN, CrN) for wear resistance

Surface texturing for specific part finishes

4. Trial Run Validation

We conduct thorough die trials to verify performance:

Press installation and setup

Initial sample inspection and adjustment

Production parameter optimization

Final sample approval process

Our integrated approach ensures reliable stamping solutions that reduce production costs and improve part quality. Contact us to discuss your stamping project requirements.