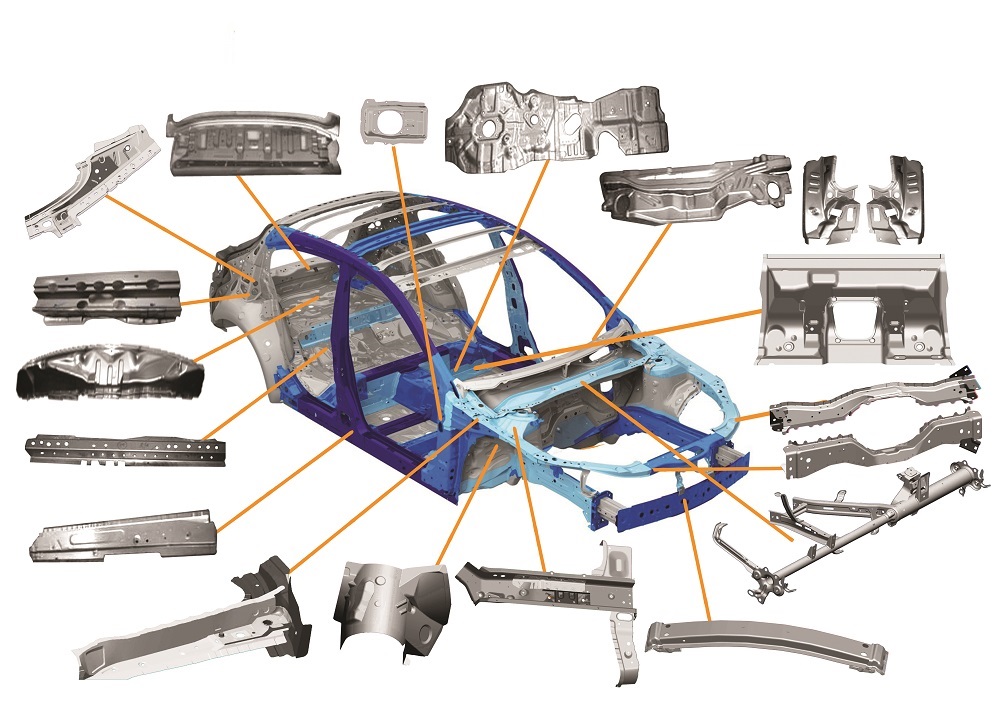

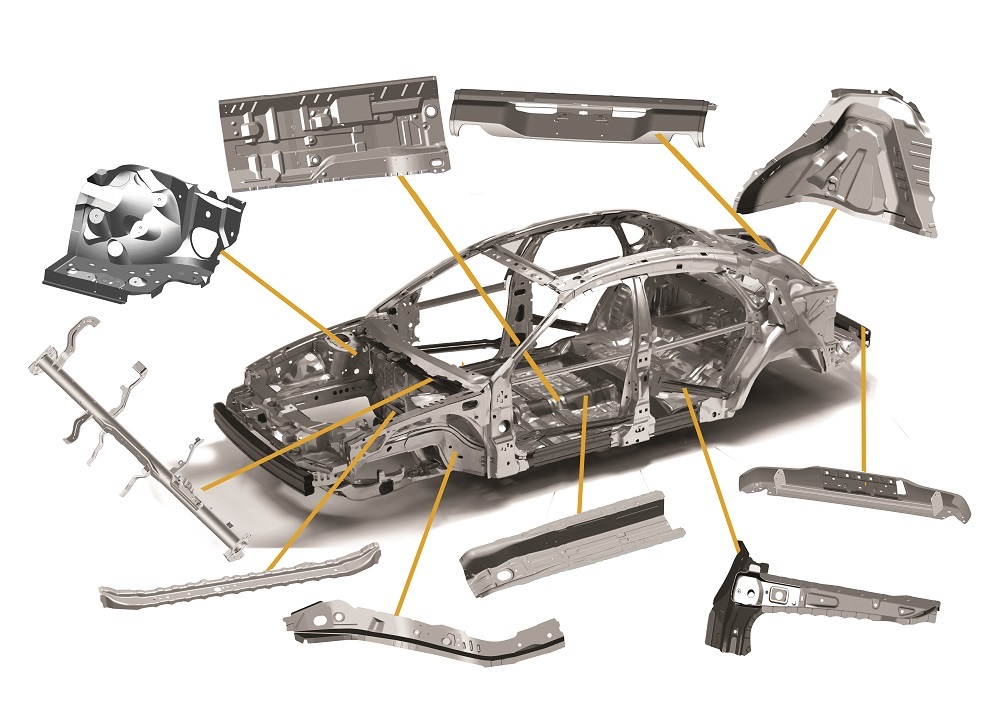

Automotive sheet metal parts are integral components used in the manufacturing of vehicles.

These parts are typically made from metal sheets that are formed into specific shapes through various processes, such as stamping, cutting and welding.

They make up many of the outer and inner structures of vehicles, including the body panels, frame parts, and other components that require strength, durability, and precision.

Common Types of Automotive Sheet Metal Parts

1. Body Panels

- Outer panels: They are typically made from high-strength steel, aluminum, or other metals for both strength and light weight.

- Inner panels: They provide structural integrity and may be hidden from view.

2. Chassis Components

- Frame parts: These are the foundational structures of a vehicle, including the cross-members, side rails, and subframes.

- Brackets and supports: These parts are used to mount various components such as the suspension system, engine, and exhaust.

3. Structural Reinforcements

- Crash protection parts: Parts like reinforcement bars, impact beams, and energy-absorbing structures designed to protect passengers during a collision.

- Underbody components: These include parts like the floor pan, firewall, and cross members, which provide structural stability and protection from road debris.

Key Manufacturing Processes for Automotive Sheet Metal Parts

1. Stamping

- Press stamping: This is one of the most common techniques, where a large press machine is used to shape metal sheets into parts by applying pressure through a die.

- Progressive stamping: This involves multiple steps in a single press, where the metal sheet moves through a series of dies to create more complex parts in one continuous process.

2. Cutting and Shearing

- Laser cutting: Laser cutting provides high precision and is often used for smaller parts or intricate designs.

3. Welding automotive sheet metal parts is a critical process in vehicle manufacturing and repair. The thin gauge metal used in automotive sheet metal parts, such as the body panels, requires specialized welding techniques to ensure strength, durability, and a good finish while minimizing heat distortion.

We are a factory with 25 years of professional experience in the production and manufacturing of automotive parts.

We provide product customization and production services.

Our strong R&D team and advanced production lines provide our customers with comprehensive services such as OEM, ODM, etc.

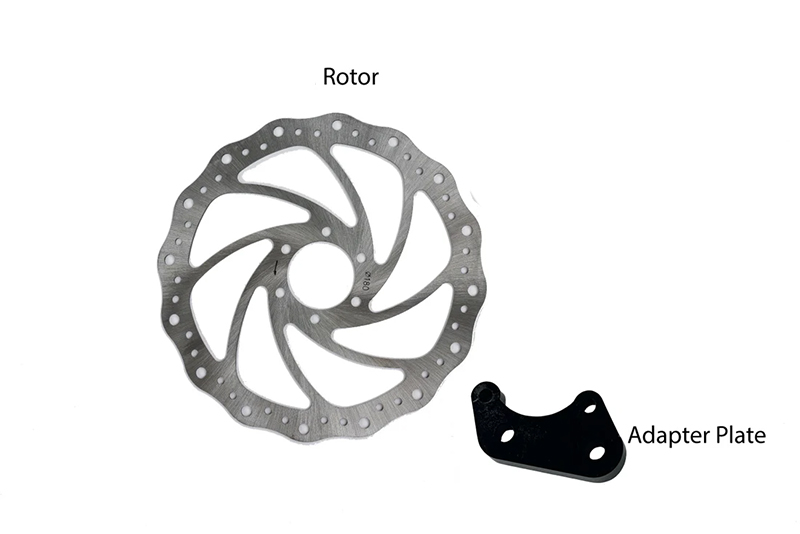

Laser cutting brake pads is an advanced technique used primarily for precision manufacturing. Laser cutting is highly accurate, providing consistent results for shaping and trimming the brake pads to specific designs.

Advantages

1. Precision: Laser cutting is highly accurate, allowing for tight tolerances and precise cuts. This is especially important for performance brake pads where specific dimensions are critical for optimal functioning.

2. Minimal Material Waste: The process is efficient, with very little material wastage. The laser only cuts where needed, maximizing the use of the raw material.

3. Customization: Laser cutting allows for complex designs, such as custom patterns on the surface of the brake pads. These designs can be made to enhance performance or aesthetics.

4. Consistency: Since the laser cutting process is computer-controlled, it ensures consistent quality and uniformity across all the brake pads produced in a batch.

5. No Contact, No Wear: Unlike traditional cutting methods, laser cutting doesn’t involve physical contact with the material. This reduces the risk of wear and tear on the tool and the potential for mechanical deformation of the brake pad.

6. Quick Prototyping: Laser cutting is ideal for rapid prototyping, enabling manufacturers to test new designs or modifications quickly without needing to create new tooling.

Our factory has a powerful 2D and 3D laser cutting production line.

We provide OEM and ODM services, including pre production samples, production, after-sales and other complete one-stop services.

Feel free to contact us anytime.

Gavin Lu