Furniture hardware refers to the components and fittings used in the construction, assembly, and functionality of furniture. These parts aren't usually the "main" parts of the furniture like wood panels or upholstery—but they're essential for how the furniture works, looks, and holds together.

Here’s a breakdown of what typically falls under furniture hardware:

Functional Hardware

These parts are critical for structure and use:

Hinges – for doors on cabinets or wardrobes

A hinge is a mechanical device that connects two solid objects—typically a door and a frame—allowing a limited angle of rotation between them, usually to open and close the door or panel.

Drawer slides – let drawers open and close smoothly

Drawer slides (also called drawer runners) are hardware components that allow drawers to open and close smoothly. They ensure that the drawer moves without resistance or wobbling, providing a clean, effortless action, and keeping the drawer aligned in its frame.

Locks and latches – for securing doors or drawers

Locks and latches are hardware mechanisms used to secure doors, drawers, or cabinets in furniture. While both serve the purpose of keeping things closed or secure, they operate in different ways and are used in various contexts.

Connectors & fasteners – screws, bolts, cam locks, etc., used for assembling parts

Connectors and fasteners are the unsung heroes of furniture—they’re what hold everything together. Whether you’re building a simple IKEA shelf or a custom dining table, these pieces of hardware are essential for assembling, stabilizing, and securing parts.

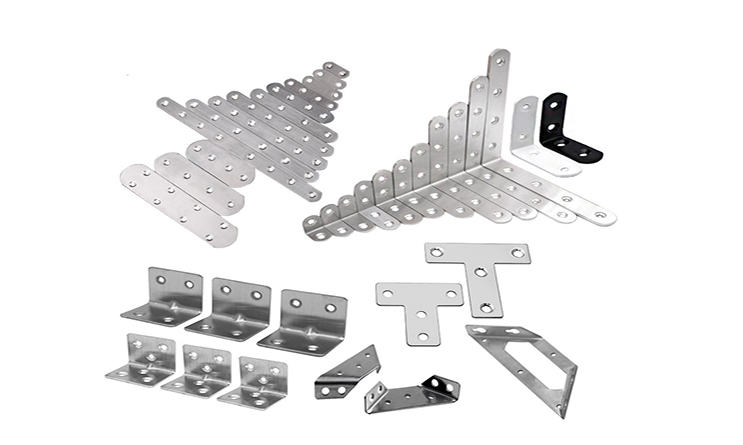

Brackets & supports – for structural reinforcement

They’re metal (sometimes plastic or wood) hardware pieces used to strengthen corners, support weight, and hold parts together at an angle—especially where joints need a little extra help.

Table metal brackets are generally made of metals with higher hardness, such as carbon steel. After laser cutting. Welding. Polishing. Made using various techniques such as spray painting. Our company can provide fully customized services.

Our technical team has more than 20 years of industry experience in stamping industry, especially for metal material mechanics has a deeper understanding, for the needs of customers, our team will need to organize new products mold design and manufacturing work, according to the drawing requirements for the design of process scheme, technological process, preparation process and quality control points instruction documents. During the design process, we are ready to provide you with review and guidance.

If you're a Furniture manufacturer in need of metal stamping services, choose ZFYL, we have created high-quality components to meet every customer's needs. To learn more about our commitment to quality, contact us today.