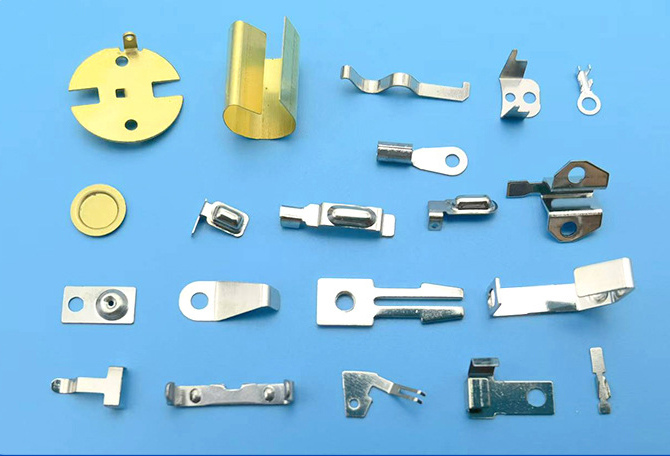

Electronic devices have different tiny parts which are extremely important and require very high accuracy. Hence metal stamping offers a precise method for manufacturing components with high precision and consistency.

Compared to other manufacturing methods, stamping is cost - effective, especially for mass production. It minimizes material waste and requires less manual intervention, reducing production costs. This makes it an ideal choice for the electronics industry, where there is a high demand for small metal components.

Once the metal stamping process takes place, the components may need an added treatment for finishing that helps to improve its durability as well as the conductivity . Some of the common treatments for surface finishing are featured below:

Electroplating may include adding a layer of zinc,nickel, gold, or tin on the metal stamped components to improve their corrosion resistance,enhanced aesthetics and better conductivity.

Anodizing involves adding a layer of oxide on the aluminum components that make the telecommunication and electrical components corrosion-resistant,wear resistance, improves durability and provides aesthetic customization with vibrant colors.

Heat treatment is required for certain metal-stamped components as it helps to improve strength.

Electronic devices often require metal enclosures for several reasons. Metals like aluminum and steel offer excellent durability and protection against physical damage, making them ideal for safeguarding sensitive components. They also provide superior electromagnetic interference (EMI) shielding, which is crucial for ensuring proper device functionality. Additionally, metal enclosures can aid in heat dissipation, helping to maintain optimal operating temperatures. Their versatile design options allow for customization to meet specific industry needs, whether for consumer electronics, industrial equipment or medical devices.

The processing of electronic device metal enclosures involves various precision manufacturing techniques.

Sheet metal stamping is suitable for mass production, offering cost efficiency and consistent quality.

Laser cutting and CNC bending offer fast prototype for custom to verify their design.

CNC machining is widely used for its high accuracy and flexibility in creating complex shapes.

Metal casting can produce intricate designs with excellent durability.

Welding and assembly processes join components to form robust structures.

Surface treatments like plating or powder coating enhance corrosion resistance and aesthetics.

Quality control is stringent to ensure enclosures meet protective and functional requirements, providing reliable protection for electronic components while supporting heat dissipation and mechanical strength.

If you're an Electronic Device manufacturer in need of metal stamping services, choose ZFYL , we have created high-quality components to meet every customer's needs. To learn more about our commitment to quality, contact us now.

Gavin Lu

Position: Sales Manager

Mobile phone: 86 15985812495

Email: sales@zfyl.com.cn

Whatsapp: 86 15985812495