Custom Metal Plate Services: Precision Solutions for Modern Manufacturing

In today’s competitive manufacturing world, precision, efficiency, and customization are key to success. Custom metal plate services have become an integral part of modern fabrication, providing tailored metal components for industries ranging from automotive and construction to machinery and energy. With advancements in cutting, forming, and surface treatment technologies, manufacturers can now deliver high-quality metal plates that meet exact design and performance specifications.

Custom metal plate services involve the processing, shaping, and finishing of metal sheets or plates to meet specific customer requirements. These services cover everything from material selection and cutting to bending, welding, and surface treatment — ensuring that each part fits perfectly into its intended application.

Common materials include carbon steel, stainless steel, aluminum, copper, and galvanized sheet, each chosen based on the desired strength, corrosion resistance, and appearance.

The Fabrication Process

The production of custom metal plates typically includes several key stages:

1. Design and Engineering – Using CAD/CAM software to create precise digital drawings and cutting programs.

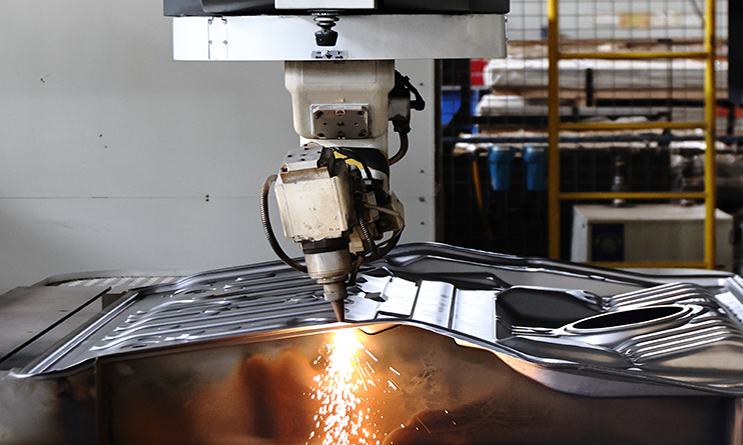

2. Cutting – Employing advanced methods such as laser cutting, plasma cutting, or waterjet cutting to achieve clean, accurate edges.

3. Forming and Bending – Using CNC press brakes to shape plates into desired angles or complex geometries.

4. Welding and Assembly – Joining multiple parts into complete assemblies when required.

5. Surface Treatment – Finishing processes such as polishing, painting, or powder coating to improve durability and aesthetics.

6. Quality Inspection – Dimensional checks and strength testing to ensure each plate meets customer and industry standards.

These steps ensure precision, consistency, and efficiency throughout the manufacturing process.

Types

Custom metal plate services can produce a wide variety of products, including:

Structural Plates: Used in construction, machinery bases, and frameworks.

Decorative Panels: Architectural or interior design applications.

Machined Components: Precision-cut and drilled plates for mechanical assemblies.

Flanges, Covers, and Brackets: Common in industrial equipment and pipelines.

Protective and Wear Plates: Designed for heavy-duty or high-impact environments.

Each type of plate can be customized in terms of thickness, shape, hole pattern, and finish to suit specific project needs.

Professional Services and Capabilities

Comprehensive metal plate service providers offer end-to-end fabrication solutions, including:

Custom design and prototyping

High-precision cutting and forming

CNC machining and drilling

Welding and full assembly

Surface finishing (anodizing, coating, plating)

Material certification and quality testing

With modern automation and digital control, companies can efficiently handle both low-volume prototypes and large-scale production runs, delivering consistent quality and fast turnaround times.

Advantages

Precision and Accuracy: CNC-controlled equipment ensures exact dimensions.

Design Flexibility: Capable of producing complex and customized geometries.

Durability: High-quality materials and finishing extend product lifespan.

Efficiency: Streamlined production reduces lead times and costs.

Versatility: Suitable for various metals and applications.

One-Stop Solution: Integrated cutting, bending, and welding reduce coordination costs.

These benefits make custom metal plate services essential for modern manufacturing and engineering projects.

Applications Across Industries

Custom metal plates are widely used in:

Automotive: Chassis components, brackets, and body panels.

Construction: Structural supports, beams, and decorative panels.

Machinery and Equipment: Bases, frames, and housings.

Energy and Oil & Gas: Flanges, tanks, and pressure vessels.

Electronics and Appliances: Enclosures and mounting plates.

Aerospace and Marine: Lightweight, corrosion-resistant parts.

From heavy industry to precision engineering, custom metal plates enable manufacturers to deliver durable, functional, and aesthetic solutions.

Conclusion

As industries continue to pursue innovation and efficiency, custom metal plate services stand out as a vital link between design and production. By integrating cutting-edge technology, skilled craftsmanship, and customer-focused engineering, these services ensure that every project — no matter how complex — is delivered with precision, reliability, and excellence.