3D bending—also known as three-dimensional tube or wire bending—is a manufacturing technique that forms metal tubes, rods, or wires into complex shapes along multiple axes. Unlike traditional 2D bending, which curves materials only within a flat plane, 3D bending enables intricate spatial geometries that meet the demands of modern engineering, design, and automation.

3D bending is the controlled deformation of metal profiles into three-axis shapes using CNC (Computer Numerical Control) machinery. These machines simultaneously manipulate rotation, feed, and bending angles to produce precise curves, spirals, loops, and multi-level structures. The result is a seamless, continuous form that maintains structural strength without the need for welding or joints.

How the 3D Bending Process Works

1. Material Loading

Tubes or wires—typically steel, stainless steel, aluminum, or copper—are fed into a CNC bending machine.

2. CNC Programming

Engineers create digital bending paths, defining exact angles, radii, lengths, and 3D coordinates.

3. Multi-Axis Motion

The machine pushes, rotates, and bends the material simultaneously. Servo-controlled systems ensure that each segment is shaped with high accuracy.

4. Quality Inspection

Laser scanning, gauges, or 3D measurement systems verify dimensional accuracy and repeatability.

This automated approach minimizes human error and allows predictable outcomes even for highly complex geometries.

Types of 3D Bending

1. Mandrel Tube Bending

Ideal for thin-walled or tight-radius bends, using an internal mandrel to prevent deformation.

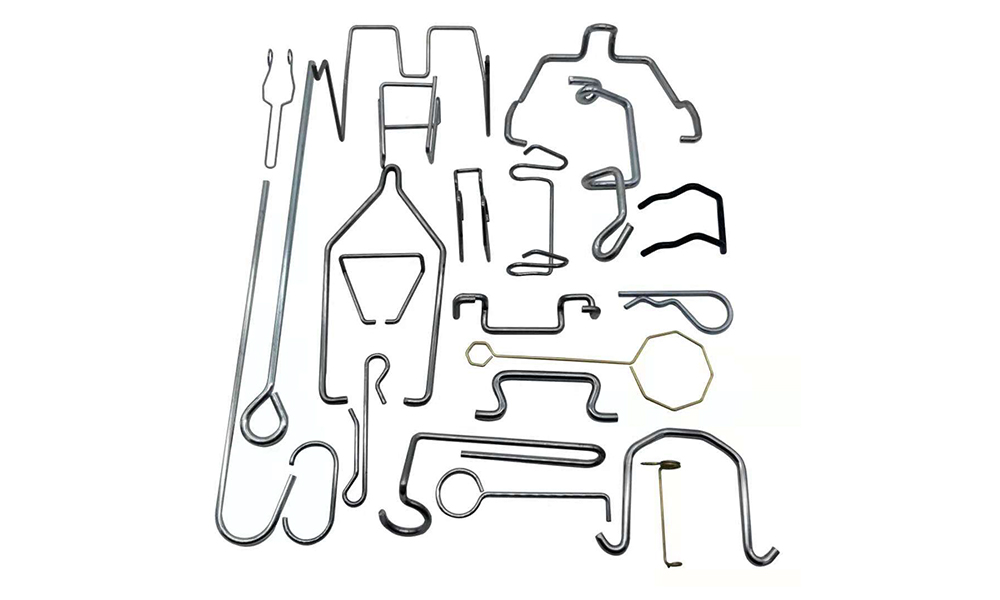

2. Wire Bending

Creates small, intricate shapes often used in consumer goods, medical devices, and mechanical components.

3. Roll Bending

Suitable for large-radius arcs or spirals by gradually forming the material through multiple rollers.

4. Freeform Bending

Uses a robotic arm to achieve curves without fixed tooling, perfect for artistic or prototype applications.

3D Bending Services

Professional 3D bending providers typically offer:

Custom tube and wire bending

CNC programming and engineering support

Prototype development

Small- to large-batch production

Material sourcing and cutting

Welding, assembly, and finishing as add-on services

These integrated services help reduce lead time and streamline production for OEMs and manufacturers.

Advantages of 3D Bending

Design Flexibility: Capable of producing complex multi-axis shapes.

High Precision: CNC control ensures tight tolerances and repeatability.

Reduced Welding: Continuous bending eliminates many joints, improving strength and aesthetics.

Cost Efficiency: Lower labor and tooling requirements compared to fabrication with multiple components.

Improved Material Integrity: Less stress and deformation compared to manual bending.

Applications of 3D Bending

3D bending is widely used across industries that require strong, lightweight, and aesthetically refined metal components:

Automotive: Exhaust systems, seat frames, fuel lines.

Furniture: Chair bases, frames, decorative structures.

Aerospace: Hydraulic lines, support structures.

Construction: Handrails, architectural elements, lighting frameworks.

Medical: Hospital bed components, instrument supports.

Consumer Products: Wire racks, display stands, appliance parts.

As industries continue to pursue lightweight designs and integrated structures, 3D bending plays an increasingly important role in modern manufacturing.