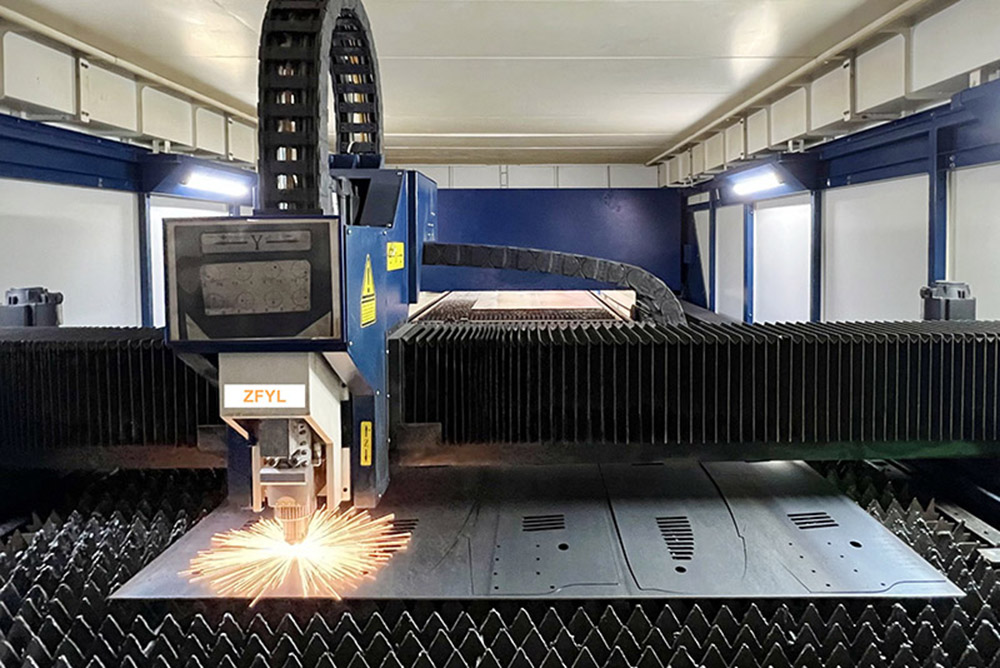

ZFYL (Xiamen) M&E Technology Co., Ltd: Advanced Laser Metal Cutting Solutions for Modern Manufacturing

As industries move toward smarter and more precise fabrication, ZFYL (Xiamen) M&E Technology Co., Ltd has established itself as a trusted provider of high-quality laser metal cutting services. With advanced equipment, experienced engineers, and a customer-focused production system, ZFYL Metal delivers reliable and efficient cutting solutions for businesses across automotive, machinery, construction, electronics, and custom metal fabrication sectors. This blog provides an in-depth look at ZFYL Metal’s laser metal cutting service—from definition and technology to advantages and real-world applications.

What Is ZFYL Metal Laser Metal Cutting?

Laser metal cutting at ZFYL Metal involves using high-power fiber laser machines to precisely cut and shape metals according to custom designs. Controlled by advanced CNC systems, the laser beam melts or vaporizes the metal along programmed paths, achieving clean edges, narrow kerfs, and highly accurate contours. This non-contact cutting method eliminates the need for mechanical blades or dies, reducing tool wear and providing excellent repeatability.

Laser Cutting Process Works

ZFYL Metal adopts a standardized and efficient workflow to ensure high production quality:

1. Design & Programming

Customers provide DWG, DXF, PDF, or 3D files. ZFYL Metal engineers optimize the drawings for laser processing, including nesting, cutting paths, and gas selection.

2. Material Preparation

ZFYL Metal supports a wide range of metals—stainless steel, carbon steel, aluminum, galvanized sheet, copper, brass, and more. Materials can be supplied by clients or sourced directly by the company.

3. Laser Cutting Operation

Fiber laser systems deliver rapid cutting speeds, stable beam quality, and high precision, even for intricate patterns or small features. Assist gases such as nitrogen, oxygen, or compressed air enhance edge quality and cutting efficiency.

4. Finishing & Inspection

After cutting, parts undergo quality checks, deburring, bending, welding, machining, or surface treatment as required.

Types

ZFYL Metal offers multiple cutting capabilities to meet diverse project needs:

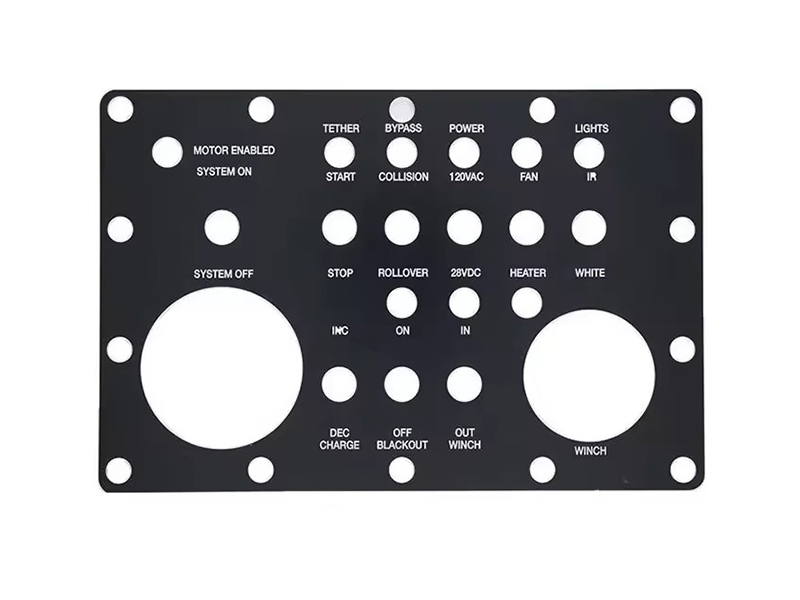

2D Metal Sheet Laser Cutting – Ideal for flat components, brackets, panels, and enclosures.

3D / Tube & Pipe Laser Cutting – Suitable for structural frames, machinery parts, and industrial tubing.

Precision & Thin-Sheet Cutting – For electronics, small components, and fine-detail parts.

Laser Engraving & Marking – Logos, text, barcodes, and identification plates.

This flexibility allows ZFYL Metal to handle both standard industrial parts and highly customized components.

ZFYL Metal’s Full-Service Metal Fabrication Capabilities

ZFYL Metal provides complete fabrication support beyond laser cutting, including:

Technical design assistance

Rapid prototyping and engineering validation

CNC bending, welding, machining, drilling, and tapping

Surface finishing (painting, powder coating, polishing, plating)

Small-batch production and mass manufacturing

Quality inspection and material certification

Fast delivery for urgent orders

With these integrated services, clients can complete entire fabrication projects in one place.

Advantages of Choosing ZFYL Metal Laser Metal Cutting

High accuracy and repeatability from advanced fiber laser machines

Smooth, burr-free edges requiring minimal post-processing

Fast throughput that shortens lead times

Strong ability to cut complex shapes and intricate designs

Wide material compatibility

Low waste and cost-efficient production

Strict quality control across every manufacturing step

These advantages enable ZFYL Metal to support both demanding industrial applications and customized creative projects.

Applications Across Industries

Automotive – brackets, structural components, body panels

Industrial machinery – frames, housings, machine parts

Construction & architecture – decorative panels, metal screens, signage

Electronics – enclosures, heat shields, precision components

Energy & HVAC – ducts, support plates, industrial hardware

Furniture & hardware – frames, decorative parts, prototypes

Custom fabrication – one-off designs, product development, artwork

From high-volume manufacturing to intricate custom projects, Our factory provides dependable, high-precision results for clients worldwide.