Metal Laser Cutting: Precision Technology Driving the Future of Manufacturing

In today’s competitive manufacturing environment, precision and efficiency are the foundation of success. Among modern metal fabrication technologies, laser cutting has rapidly become one of the most advanced and widely adopted processes worldwide. From automotive and aerospace to construction and custom fabrication, metal laser cutting continues to redefine how industries shape, design, and produce components.

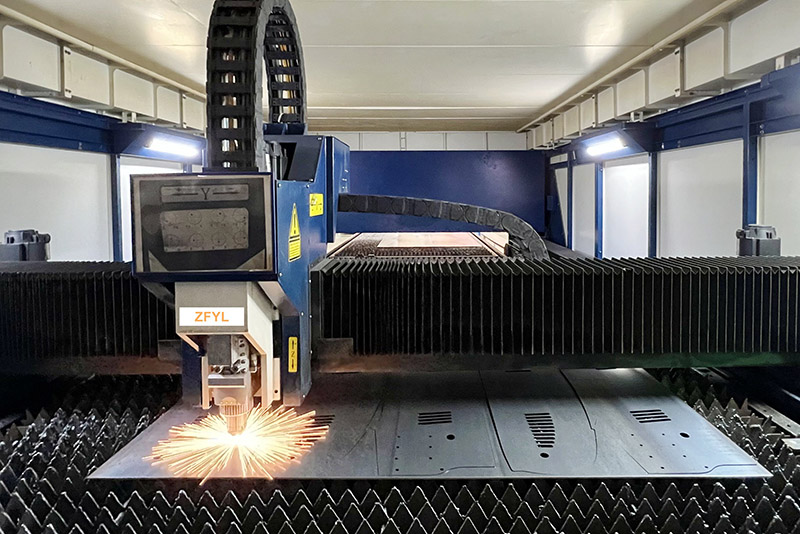

Metal laser cutting is a non-contact manufacturing process that uses a concentrated beam of light to cut through metal materials with exceptional precision. The laser, guided by computer numerical control (CNC), melts, burns, or vaporizes the material along programmed paths to create clean, accurate cuts with minimal waste.

Unlike traditional cutting methods that rely on physical tools, laser cutting uses energy instead of mechanical force. This eliminates tool wear, reduces distortion, and allows manufacturers to achieve complex geometries and fine details that were once difficult or impossible with conventional equipment.

The Laser Cutting Process

A typical laser cutting system consists of three key elements:

Laser Source – Generates a focused beam of high-intensity light. Common types include fiber lasers, CO₂ lasers, and Nd:YAG lasers.

Beam Delivery System – Mirrors and lenses direct and focus the beam onto the workpiece.

CNC Control and Assist Gas – The cutting head moves precisely along programmed coordinates while gases like oxygen, nitrogen, or air assist in expelling molten material and improving edge quality.

Depending on the setup, metal laser cutting can be performed in 2D (flat sheet cutting) or 3D (multi-axis cutting) formats, offering flexibility for both simple and complex parts.

Advantages

Laser cutting is valued across industries for its combination of speed, accuracy, and adaptability.

High Precision: Achieves dimensional tolerances as tight as ±0.02 mm.

Superior Edge Quality: Produces clean, burr-free edges with no need for post-processing.

Speed and Efficiency: Ideal for both prototyping and mass production, especially in thin to medium metal sheets.

Material Flexibility: Works with carbon steel, stainless steel, aluminum, copper, brass, titanium, and more.

Design Flexibility: Easily handles intricate shapes, logos, and custom patterns through CAD/CAM integration.

Minimal Heat Distortion: Concentrated laser energy reduces the heat-affected zone, preserving material integrity.

Automation Ready: Integrates seamlessly with robotic systems and smart factories for high-volume, unattended production.

These benefits make laser cutting one of the cornerstones of modern digital manufacturing.

Applications

Metal laser cutting has become indispensable across a wide range of industries:

Automotive: Body panels, chassis parts, exhaust components, brackets, and prototypes.

Aerospace: Lightweight structural parts, turbine components, and precision enclosures.

Construction and Architecture: Decorative metal panels, signage, and structural fittings.

Electronics: Enclosures, heat sinks, and precision components.

Machinery and Equipment: Gears, machine frames, housings, and tooling plates.

Furniture and Interior Design: Custom patterns, decorative panels, and artistic metalwork.

The growing use of laser cutting in electric vehicles (EVs) and renewable energy components further highlights its strategic role in the global shift toward sustainable manufacturing.

Service Capabilities and Market Growth

Modern metal laser cutting service providers are more than just fabricators — they act as technology partners, helping clients from design optimization to final production. Many now offer integrated solutions that combine laser cutting, CNC bending, welding, surface treatment, and assembly, providing one-stop manufacturing support.

According to industry analysts, the global metal laser cutting market is expected to grow steadily over the next decade, driven by trends in automation, precision engineering, and customization. The adoption of high-power fiber lasers, AI-driven nesting software, and fully automated cutting systems is transforming workshops into smart manufacturing hubs.

Conclusion

Metal laser cutting represents the perfect balance of precision, flexibility, and productivity. As manufacturers face increasing demands for customization, lightweight design, and sustainability, laser cutting will continue to lead innovation in metal fabrication. Whether it’s mass production or one-off prototypes, this technology enables businesses to achieve faster turnaround, superior quality, and greater design freedom — defining the future of modern manufacturing.