Stamped metal plates are fundamental components across manufacturing, construction, electronics, and automotive sectors. These parts, created through precision stamping technology, deliver exceptional accuracy, repeatability, and cost efficiency. With industries demanding lighter, stronger, and more durable materials, stamped metal plates have evolved from basic flat parts into complex, high-performance components that support global production lines.

Definition

A stamped metal plate is a piece of metal that has been formed, cut, embossed, or engraved using a stamping press and dies to achieve a precise shape or surface design. Stamping can involve several operations—blanking, piercing, bending, coining, or embossing—depending on the product’s function. These plates can serve as structural components, identification tags, electronic housings, mounting bases, or decorative elements.

Stamped plates may be made from steel, aluminum, copper, brass, stainless steel, titanium, or specialized alloys. The process allows high repeatability and low per-unit cost once the tooling is completed, making it ideal for mass production in industries requiring tight tolerances.

Manufacturing Process

1. Material Selection:Choosing the right metal depends on strength, corrosion resistance, conductivity, and cost.

Steel / Stainless steel: Strength and durability for industrial plates.

Aluminum: Lightweight and corrosion-resistant.

Copper / Brass: Electrical and decorative applications.

2. Die Design and Tooling

Engineers create custom dies to define the part’s geometry. These dies—often made from hardened tool steel—are installed in a stamping press. Computer-aided design (CAD) and computer-aided manufacturing (CAM) ensure micron-level accuracy.

3. Stamping Operations

Blanking: Cutting raw sheets into desired outlines.

Piercing: Creating holes or slots.

Forming / Bending: Giving three-dimensional shape.

Embossing / Coining: Adding surface textures or raised lettering.

Deep drawing: Forming complex curved shapes without cracking.

4. Secondary Processes

After stamping, parts may undergo deburring, heat treatment, surface coating, anodizing, plating, or painting to enhance durability and appearance.

5. Inspection and Quality Control

Dimensional inspection, tensile testing, and surface checks guarantee that stamped plates meet design and regulatory standards. Automated optical inspection and coordinate measuring machines (CMM) are commonly used.

Classification

Stamped metal plates can be categorized in several ways:

1. By Material Type

Ferrous: Carbon steel, stainless steel.

Non-ferrous: Aluminum, copper, brass, titanium.

2. By Manufacturing Method

Single-operation stamping: Each press stroke performs one action.

Progressive die stamping: Multiple forming stages in one continuous process—ideal for high volumes.

Compound die stamping: Multiple cutting and forming operations in one stroke for precision parts.

3. By Application

Identification plates (nameplates, data tags).

Functional plates (mounting brackets, machine covers).

Decorative plates (logos, signage, trim).

Electronic / automotive components (heat sinks, terminals, housings).

Services and Support

Modern stamping companies offer a range of value-added services beyond fabrication:

Design & Engineering Support: CAD/CAM assistance to optimize geometry for strength and material savings.

Prototype Development: Rapid prototyping and small-batch runs for design validation before mass production.

Tooling Maintenance & Modification: Continuous improvement of dies for consistent results.

Surface Finishing & Engraving: Laser engraving, chemical etching, or embossing for branding or functional labeling.

Assembly & Packaging: Integration with fasteners or adhesives for turnkey delivery.

Supply Chain Services: Just-in-time (JIT) delivery, warehousing, and international logistics.

Advantages

1. High Precision and Consistency

Stamping achieves repeatable accuracy with tight tolerances—ideal for complex assemblies.

2. Cost-Effective for Mass Production

Once tooling is established, per-part costs drop sharply, supporting high-volume manufacturing.

3. Material Efficiency

Optimized die design reduces waste, and scrap metal is recyclable.

4. High Strength and Durability

Work-hardening during stamping can increase the strength of metals without adding weight.

5. Versatile Design Possibilities

Embossing, engraving, and shaping allow manufacturers to integrate function and aesthetics in one operation.

6. Scalability and Automation

Modern stamping lines with robotic feeding and monitoring systems ensure continuous, automated production with

minimal human error.

Applications

Stamped metal plates are ubiquitous in modern industry, serving both structural and decorative purposes:

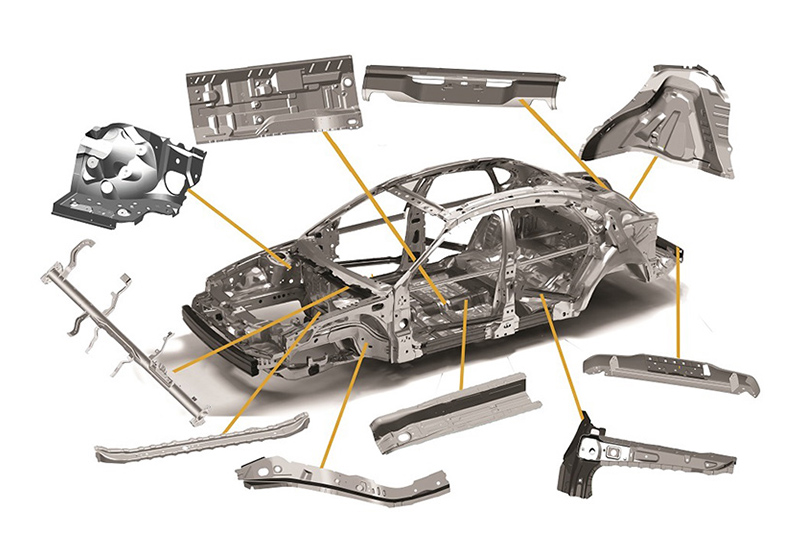

Automotive Industry: Body panels, brackets, seat frames, heat shields, VIN plates.

Electronics: Casings, connectors, shielding plates, and heat dissipation components.

Machinery and Equipment: Mounting plates, housings, covers, and base frames.

Construction: Nameplates, architectural trims, façade panels, switch plates.

Aerospace: Lightweight precision parts requiring high strength-to-weight ratios.

Consumer Products: Branding tags, appliance panels, and customized product labels.

In many fields, stamped metal plates outperform plastic or cast components thanks to superior mechanical integrity and environmental resilience.

Future Trends

Integration of Smart Manufacturing: IoT-enabled presses track production data for predictive maintenance and quality optimization.

Lightweight Alloys & Hybrid Materials: Aluminum-magnesium and titanium alloys reduce weight while maintaining strength.

Precision Micro-Stamping: Growing in electronics and medical device production.

Sustainable Manufacturing: Recycled metals, low-energy stamping presses, and waste reduction initiatives.

Conclusion

Stamped metal plates exemplify how traditional metalworking has merged with modern technology to meet evolving industrial needs.

Combining precision, scalability, and durability, they remain indispensable in countless sectors—from vehicles and electronics to construction and consumer goods.

As automation, material science, and sustainability continue to advance, stamped metal plates will play an even greater role in shaping the future of efficient, high-performance manufacturing.