As industries continue to advance toward higher precision and faster production cycles, ZFYL Metal has become a trusted provider of professional laser cutting solutions. Equipped with modern CNC laser systems and years of fabrication experience, ZFYL Metal delivers fast, accurate, and reliable cutting services for clients across automotive, construction, machinery, and custom manufacturing fields. This blog introduces what ZFYL Metal laser cutting service offers—from the cutting process and service capabilities to advantages and real-world applications.

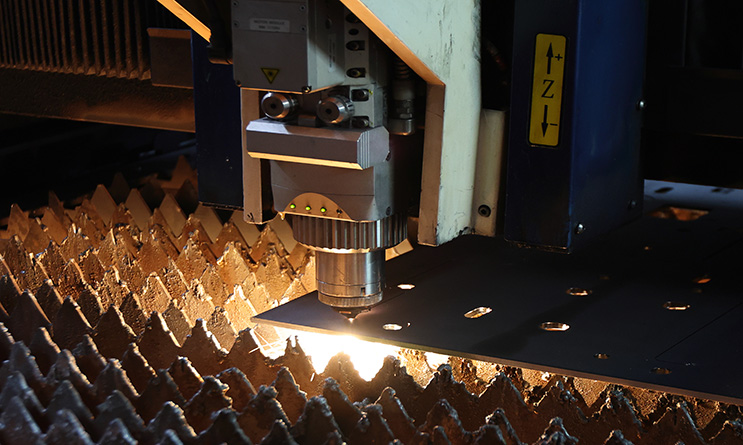

Our factory laser cutting service uses high-power fiber laser machines to cut, shape, and engrave metal sheets with outstanding accuracy. By converting customer designs into CNC programs, ZFYL Metal ensures every detail is reproduced with precision. The laser generates a concentrated beam that melts or vaporizes the metal along the programmed path, producing extremely clean edges and smooth surfaces without physical contact.

Laser Cutting Process Works

ZFYL Metal follows a structured process to guarantee consistent quality:

1. Design and Programming

Customers provide 2D files (DXF, DWG, PDF, AI), which ZFYL engineers convert into optimized CNC code for efficient nesting and material use.

2. Material Preparation

Our company supports stainless steel, carbon steel, aluminum, galvanized sheet, and other engineering metals, offering on-site material sourcing if needed.

3. High-Precision Cutting

Fiber laser equipment delivers fast cutting speeds and stable performance, capable of fine details, tight tolerances, and complex geometries.

4. Inspection and Finishing

Each part undergoes quality checks, with optional bending, welding, drilling, tapping, and surface finishing services provided for complete fabrication support.

Types

We provides multiple cutting approaches to meet different project requirements:

2D Metal Sheet Laser Cutting – Ideal for flat panels, brackets, enclosures, and precision parts.

3D Laser Cutting / Tube & Pipe Cutting – For round, square, and custom-shaped tubes used in machinery and structural components.

Laser Engraving & Marking – Logos, serial numbers, and identification marks.

Prototype and Fine-Cut Processing – For small-batch high-precision components.

Capabilities

A full suite of services is available, including:

Custom design consultation

CNC laser cutting for metals up to required thickness

Bending, welding, machining, and assembly integration

Surface finishing such as polishing, sandblasting, and coating

Rapid prototyping and high-volume production

Material sourcing and quality inspection

Same-day or short-lead-time delivery for urgent orders

These services make ZFYL Metal a one-stop metal fabrication partner.

Advantages

ZFYL Metal provides unique benefits built on technology and expertise:

High precision and consistency supported by advanced fiber lasers

Clean, burr-free edges requiring minimal finishing

Fast turnaround due to optimized nesting and efficient workflows

Versatile material compatibility with multiple metal types

Low waste and cost efficiency from precise cutting paths

Ability to create complex shapes that traditional tools cannot achieve

Stable quality control throughout the entire production process

These advantages enable customers to reduce production time while maintaining high product quality.

Applications

ZFYL Metal laser cutting service supports a vast range of industries and products, including:

Automotive parts such as brackets, supports, and structural plates

Machinery components and industrial equipment panels

Construction and architectural metalwork, including decorative screens

Electrical enclosures and precision metal housings

Furniture and hardware parts

Custom prototypes for R&D and product development

Retail displays and signage with intricate patterns and lettering

Whether the project involves heavy-duty industrial components or delicate decorative designs, our factory cutting technology delivers exceptional accuracy and repeatability.