Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

CNC bend factory provide cnc metal tube bending service CNC bending factory made in China Our factory provide cnc tube bending service CNC bending service available CNC Bend OEM Best quality cnc metal bending

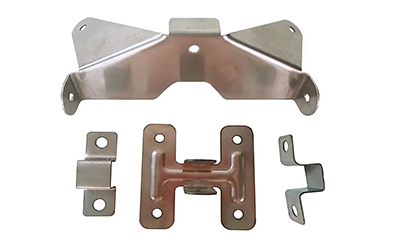

Provide OEM ODM service for metal stamping,stainless steel stamping. Our factory has over 25 years of experience in precision sheet metal stamping. High volume metal stamping with factory price. High precision metal stamping made in China.

High Volume High Precision 304 Stainless Steel Sheet Metal Stamping

Stainless steel stamping is a manufacturing process where stainless steel sheets are fed into a machine that shapes or cuts the metal into specific forms using a die and press. It’s a versatile process used to produce high-precision parts and components for a wide range of industries, including automotive, electronics, aerospace, and medical.

Here are some of the key details about stainless steel stamping:

1. Types of Stamping Processes:

Blanking: Cutting flat pieces from a larger sheet of stainless steel.

Piercing: Creating holes or openings in the material.

Bending: Forming the material by bending it to a specific angle.

Embossing: Creating raised or recessed designs on the surface.

Deep Drawing: A process to form deep, hollow parts by drawing the material into a die.

Coining: Applying high pressure to shape or mark the material with intricate details.

2. Applications:

Automotive: Parts like trim, brackets, panels, and connectors.

Electronics: Components such as connectors, housings, and clips.

Medical Devices: Surgical instruments, implants, and sterilization trays.

Aerospace: Parts for aircrafts such as brackets, frames, and housings.

Consumer Goods: Kitchen appliances, sinks, or decorative items.

3. Advantages of Stainless Steel Stamping:

Durability: Stainless steel is resistant to corrosion, making it suitable for harsh environments.

Precision: High-precision parts can be made, which is essential for many industries.

Efficiency: The process can be automated for large production runs, which lowers manufacturing costs.

Flexibility: Complex shapes and intricate details can be stamped without additional machining.

4. Challenges:

Tool Wear: The hard nature of stainless steel can cause faster wear on stamping tools.

Cost: Stainless steel can be more expensive compared to other materials.

Forming Limitations: Stamping processes may have limitations when it comes to forming very deep or complex shapes.

How to custom Stamping Parts:

Send us detailed drawing or original samples.

Advise the types of material and surface treatment, also your order quantity.

Our experienced engineers will make the detailed analyzation and issue the best solution for the cost and production base on the informations you provided.

Prototype production.

Prototype approval (precision sheet metal stamping).

Engineering change and re-design services (If need).

Mass production ( high volume metal stamping).

If you have metal stamping wholesale, stamping 304 stainless steel, precision sheet metal stamping,high volume metal stamping, high precision metal stamping request.

Please kindly contact us to inquiry,we will offer you best quality products and competitive price.