Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

CNC bend factory provide cnc metal tube bending service CNC bending factory made in China Our factory provide cnc tube bending service CNC bending service available CNC Bend OEM Best quality cnc metal bending

Provide OEM ODM service for metal stamping,stainless steel stamping. Our factory has over 25 years of experience in precision sheet metal stamping. High volume metal stamping with factory price. High precision metal stamping made in China.

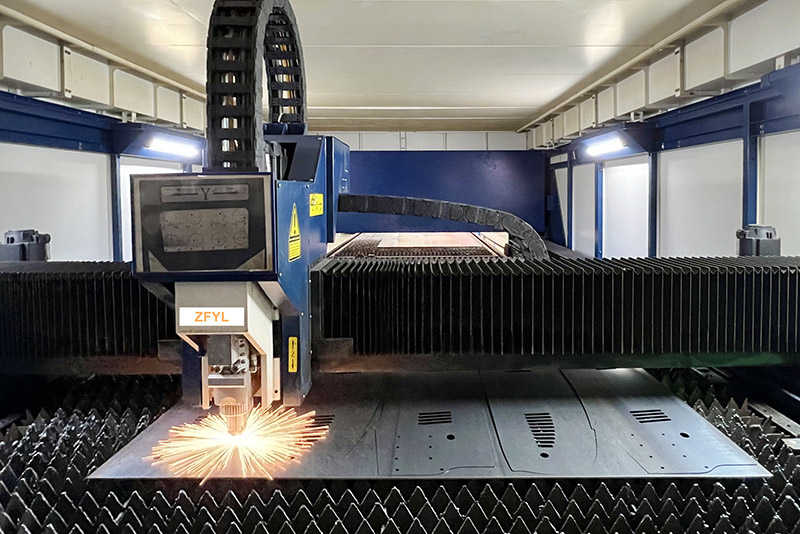

Custom Metal Laser Cutting Service

Metal laser cutting is a precise and efficient method used for cutting metal sheets and plates. It uses a high-powered laser beam to melt or vaporize the material, allowing for clean, intricate cuts with minimal distortion.

Stainless Steel: Excellent for its corrosion resistance and strength.

Aluminum: Lightweight and has good thermal conductivity.

Carbon Steel: Commonly used for its strength and durability.

Brass and Copper: Used for applications requiring high electrical conductivity.

Laser Generation: A laser cutting machine generates a laser beam using a laser source, often a fiber laser or CO2 laser.

Beam Focus: The laser beam is focused onto the metal surface through a series of mirrors and lenses.

Material Interaction: The concentrated laser beam heats the metal to the point where it melts or vaporizes. An assist gas, such as oxygen or nitrogen, is often blown through the cut to blow away the molten material and improve the cut quality.

Cut Path: The machine moves the laser beam along a programmed path to create the desired cut shape.

Precision: Capable of producing intricate and accurate cuts with tight tolerances.

Speed: Faster than traditional cutting methods, especially for complex designs.

Minimal Waste: The precision of the cuts reduces material wastage.

Versatility: Can cut through various thicknesses and types of metal.

Laser cutting brake pads is a precise and efficient manufacturing process used in the automotive and industrial sectors.

Why Use Laser Cutting for Brake Pads?

1. Precision

Laser cutting offers micrometer-level accuracy, ensuring consistent pad shapes.

Useful for complex geometries like slots, chamfers, and wear indicators.

2. Speed & Efficiency

Faster than traditional stamping or milling for small to medium production runs.

Reduced tool wear compared to mechanical methods.

3. Material Flexibility

Can cut friction material (non-metallic composites), backplates (usually steel or aluminum), and

shims.

Custom laser cutting typically refers to a fabrication process where a high-powered laser is used to cut, engrave, or mark materials based on custom designs. Here's a quick guide on what it includes and how you can get started:

How It Works

1. Design Creation: Use software like Adobe Illustrator, CorelDRAW, or CAD to create vector files (usually in formats like SVG, DXF, or AI).

2. Upload to Service or Machine: Either send the file to a laser cutting service or upload it to your own laser cutter (e.g., Glowforge, Epilog, or Boss Laser).

3. Material Placement & Settings: Place the material, adjust focus, speed, and power.

4. Cut or Engrave: The laser follows the design paths.

If you’re looking for a specific custom laser cutting service or have a design in mind, I can help you explore options or guide you through creating the design for your project!