Custom CNC Cutting Services: Precision Engineering for the Modern Industry

As industries demand greater precision and productivity, custom CNC cutting services have become a cornerstone of modern manufacturing. Combining advanced automation with high-speed machining, CNC cutting provides unmatched accuracy, efficiency, and flexibility — enabling manufacturers to transform metal, plastic, and composite materials into precision-engineered components for diverse industries.

CNC cutting (Computer Numerical Control cutting) is a manufacturing process that uses computer-guided machines to cut, shape, and drill materials according to digital design files. The system interprets CAD/CAM programs and controls cutting tools or lasers to produce parts with extremely tight tolerances.

Unlike manual cutting, CNC systems deliver repeatable precision, ensuring consistent quality across every part. Whether for one-off prototypes or mass production, CNC cutting enables efficient fabrication of complex geometries that traditional methods cannot achieve.

The CNC Cutting Process

A typical custom CNC cutting process involves several key steps:

1. Design and Programming – Engineers create 2D or 3D digital models using CAD software and convert them into machine-readable code.

2. Material Preparation – Sheets, plates, or blocks of metal, plastic, or composite are securely positioned on the cutting bed.

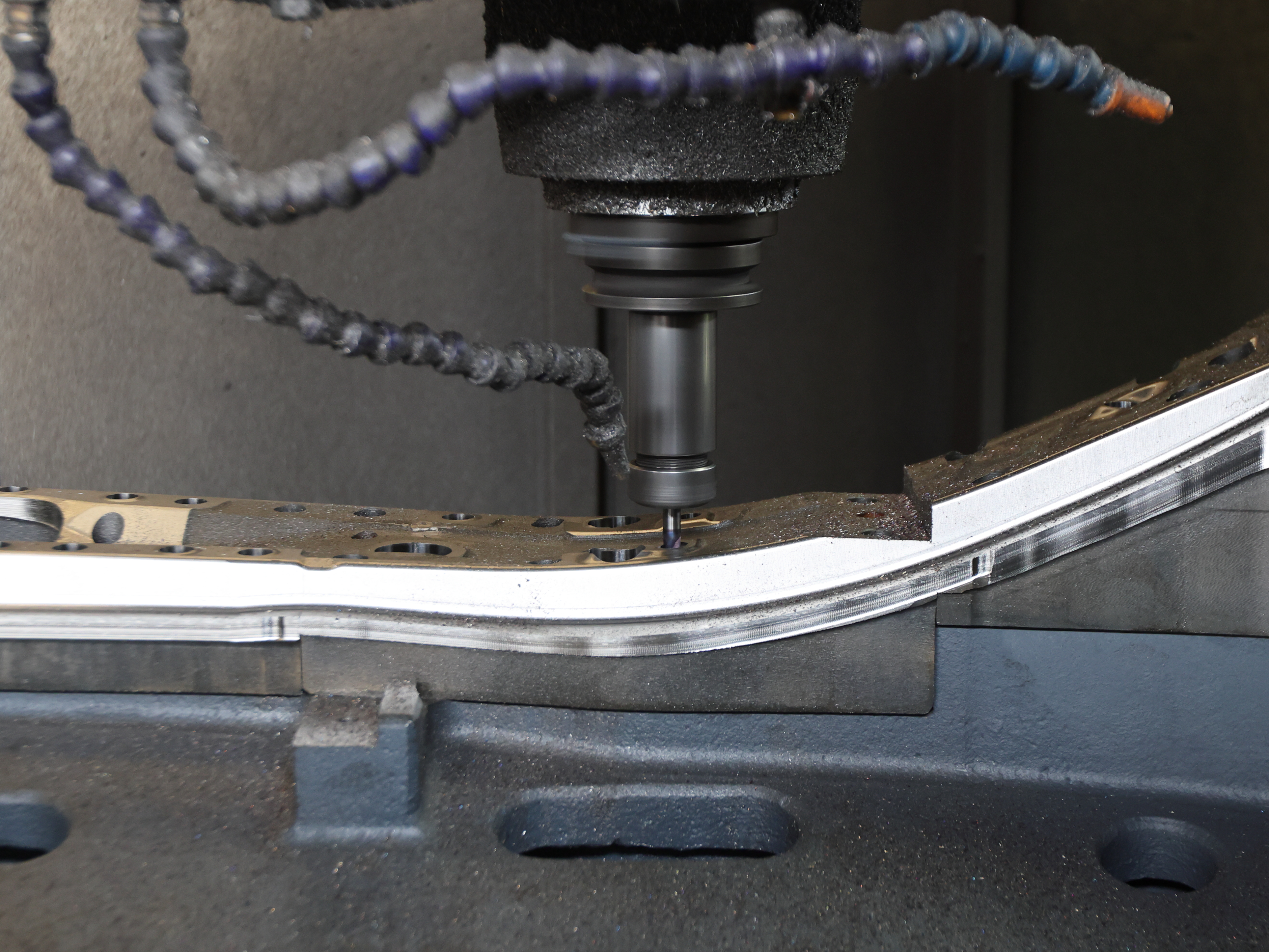

3. Cutting Operation – The CNC machine executes programmed tool paths using laser, plasma, waterjet, or router cutting.

4. Finishing and Deburring – Edges are smoothed, holes are tapped, and surfaces may be treated to meet design specifications.

5. Quality Inspection – Precision measurement and dimensional checks ensure each part meets required tolerances.

This automated workflow minimizes errors and material waste while maximizing speed and consistency.

Types of CNC Cutting

Different CNC cutting methods are used depending on the material and application:

Laser Cutting: Ideal for thin metals and intricate shapes; offers fine, clean edges.

Plasma Cutting: Suitable for thicker metals with fast cutting speed and cost efficiency.

Waterjet Cutting: Uses high-pressure water with abrasives to cut without heat distortion.

Router Cutting: Commonly used for wood, plastics, and aluminum sheets.

CNC Milling and Engraving: For detailed profiles and precision machining.

Each cutting technique delivers unique benefits — from high-speed mass production to ultra-precise prototyping.

Custom CNC Cutting Services

Professional CNC cutting providers offer end-to-end fabrication solutions tailored to diverse client requirements. Core services include:

Custom design and CAD/CAM programming

High-precision laser, plasma, and waterjet cutting

CNC machining, drilling, and milling

Edge finishing, bending, and welding integration

Prototype and mass production capabilities

Material sourcing and quality inspection

These services support industries that require both functional and aesthetic excellence, ensuring timely delivery and reliable performance.

Advantages of CNC Cutting

High Precision and Consistency: Ensures accurate, repeatable results across batches.

Design Flexibility: Supports complex shapes, holes, and contours with ease.

Efficiency: Fast operation and minimal material waste.

Automation: Reduces human error and improves production speed.

Versatility: Compatible with metals, plastics, composites, and more.

Cost-Effective: Lower labor and rework costs compared to manual fabrication.

With digital integration, CNC cutting also supports smart manufacturing, enabling real-time monitoring, data tracking, and improved process optimization.

Applications Across Industries

Custom CNC cutting is widely used in various sectors, including:

Automotive: Chassis, brackets, and body components.

Construction: Architectural panels, frames, and structural parts.

Aerospace: Lightweight aluminum and titanium components.

Machinery: Precision machine parts and enclosures.

Electronics: Housings, plates, and heat sinks.

Signage and Art Design: Decorative panels and custom lettering.

Whether for industrial strength or aesthetic design, CNC cutting ensures that every product meets the highest standards of precision and performance.

Conclusion

In the age of digital manufacturing, custom CNC cutting services represent the perfect balance between technology and craftsmanship. By integrating intelligent automation, advanced materials, and expert engineering, CNC cutting delivers solutions that are faster, more accurate, and more adaptable than ever before — driving innovation across every corner of the manufacturing world.