CNC Services: Driving Precision Manufacturing in the Modern Industrial Era

As global manufacturing continues to evolve toward higher efficiency and tighter tolerances, CNC services have become a cornerstone of modern production. From automotive components to aerospace structures and consumer electronics, industries rely on CNC machining for precision, consistency, and rapid turnaround. This article explores the definition of CNC services, their core processes, classifications, and the advantages and applications that make CNC technology indispensable in today’s industrial landscape.

What Are CNC Services?

CNC (Computer Numerical Control) services involve manufacturing operations performed using automated, computer-controlled machines. By converting digital designs into machining commands, CNC equipment can cut, mill, drill, shape, or finish materials with exceptional accuracy. This automation eliminates many of the limitations of manual machining, enabling consistent, repeatable, and complex production at both prototype and mass-manufacturing levels.

How CNC Machining Works

The CNC machining process starts with CAD/CAM programming, where engineers create or import a digital drawing and convert it into tool paths. Once the program is loaded into the CNC machine, the system controls the movement of tools and axes to shape the part. Real-time sensors, servo motors, and feedback systems ensure stability, accuracy, and consistency throughout the cycle. After machining, parts may undergo inspection, deburring, surface finishing, or assembly.

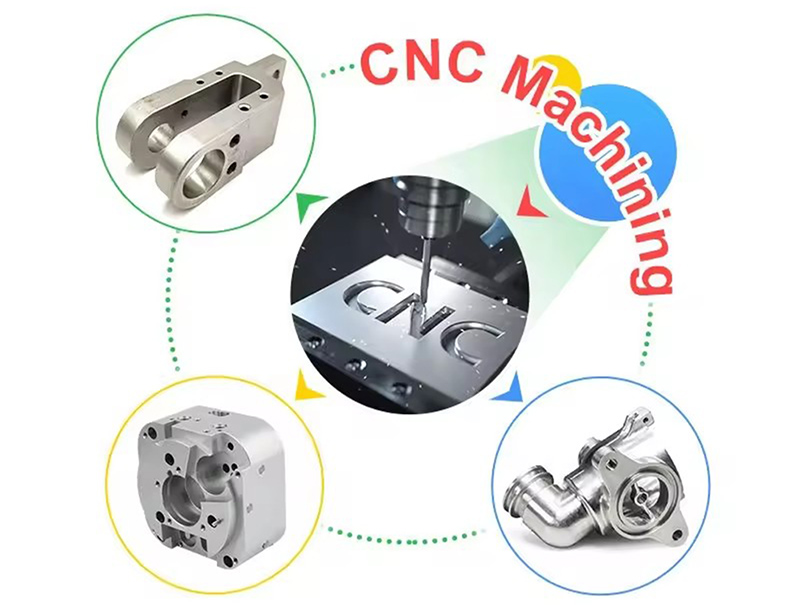

Types of CNC Services

CNC manufacturing includes several major categories:

CNC Milling – Uses rotating tools to remove material from various angles, ideal for pockets, slots, contours, and 3D surfaces.

CNC Turning – Rotates the workpiece to form cylindrical shapes such as shafts, pins, and bushings.

5-Axis Machining – Enables complex, multi-angle cutting for aerospace, medical, and precision engineering.

CNC Grinding – Produces ultra-fine finishes and tight dimensional control.

CNC Laser Cutting and Plasma Cutting – For high-speed cutting of metal sheets.

EDM (Electrical Discharge Machining) – Specialized cutting for hard metals and intricate shapes.

Each method supports unique industry requirements and design complexities.

CNC Service Capabilities

Modern CNC service providers typically offer:

CAD/CAM design support

Prototyping and engineering validation

Small-batch and high-volume machining

Multi-axis machining for complex geometries

Surface treatments such as anodizing, powder coating, polishing, and plating

Assembly, testing, and quality documentation

This full-service approach allows customers to streamline production with a single supplier.

Advantages of CNC Services

CNC technology offers multiple benefits:

High precision and repeatability across thousands of parts

Fast and efficient production, reducing lead times

Capability for complex and intricate shapes

Lower risk of human error

Compatibility with metals, plastics, and composites

Cost-effective scaling from prototype to mass production

These strengths make CNC machining one of the most reliable manufacturing methods available today.

Industry Applications

CNC services support a broad range of sectors, including:

Automotive – structural components, brackets, engine parts

Aerospace – high-precision, lightweight machining

Electronics – housings, heat sinks, custom fixtures

Medical devices – surgical tools and implant components

Industrial machinery – gears, frames, custom mechanical parts

Robotics and automation – precision movement components

From early-stage product development to large-scale production, CNC services continue to push the boundaries of modern manufacturing.