Welding and Fabrication: Building the Backbone of Modern Industry

Welding and fabrication are the unsung heroes of modern manufacturing. From skyscrapers and bridges to automobiles and machinery, nearly every industrial product depends on the precision and strength of fabricated metal components. As industries pursue higher quality, efficiency, and automation, welding and fabrication services continue to evolve, driving innovation and shaping the future of metal engineering.

Metal fabrication refers to the process of shaping raw metal materials into finished structures or components. It includes cutting, bending, forming, machining, and assembling to produce parts that meet specific design requirements.

Welding, a core part of fabrication, is the process of joining two or more metal parts together by applying heat, pressure, or both. The goal is to create a permanent, strong bond that can withstand mechanical stress and environmental factors. Together, welding and fabrication form the foundation of metalworking — transforming ideas and blueprints into durable, functional products.

The Fabrication Process

Design and Engineering – Using CAD/CAM software to create detailed drawings and production plans.

Cutting and Preparation – Metal sheets or tubes are cut using laser cutting, plasma cutting, or sawing.

Forming and Bending – CNC press brakes or rollers shape materials into required geometries.

Welding and Assembly – Components are joined through various welding techniques.

Finishing and Inspection – Includes grinding, coating, painting, and quality testing to ensure durability and aesthetics.

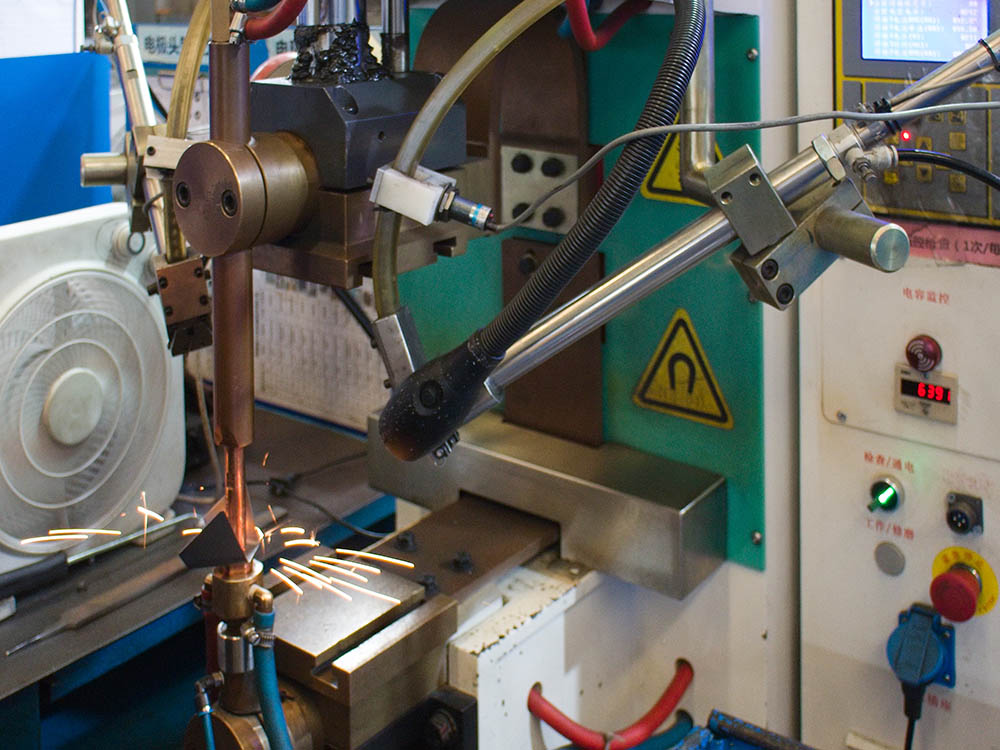

Modern workshops increasingly integrate CNC automation, robotic welding, and digital monitoring systems, ensuring precision, consistency, and traceability in every project.

Types of Welding

MIG Welding (Metal Inert Gas): Fast and efficient, ideal for large-scale production.

TIG Welding (Tungsten Inert Gas): Offers high precision and clean welds, perfect for thin metals or stainless steel.

Stick Welding (SMAW): Versatile and portable, often used in construction and maintenance.

Spot Welding: Commonly applied in the automotive industry for joining sheet metal.

Laser and Robotic Welding: Advanced, high-speed, and precise, widely adopted in automated manufacturing lines.

Each method balances strength, cost, and efficiency, allowing manufacturers to select the optimal approach for each project.

Services and Capabilities

Professional welding and fabrication service providers offer comprehensive solutions, including:

Custom metal fabrication for industrial structures and equipment

Precision welding and assembly for mechanical components

Structural steel fabrication for buildings and infrastructure

Sheet metal processing including cutting, forming, and surface finishing

Prototyping and mass production support for OEM clients

Many companies now provide end-to-end services, from material sourcing to on-site installation, ensuring customers receive complete, ready-to-use solutions.

Advantages

Strength and Durability: Welded joints maintain structural integrity under heavy loads.

Design Flexibility: Supports complex geometries and customized designs.

Cost Efficiency: Automated processes reduce labor and production time.

Versatility: Applicable to a wide range of materials — steel, stainless steel, aluminum, copper, and alloys.

Scalability: Suitable for both prototype and large-scale production.

Applications Across Industries

Automotive and Transportation: Chassis, exhaust systems, and frame assemblies.

Construction and Infrastructure: Beams, columns, and structural frames.

Machinery and Equipment: Tanks, conveyors, and industrial housings.

Energy and Oil & Gas: Pipelines, pressure vessels, and offshore structures.

Aerospace and Defense: Lightweight, high-strength assemblies.

Architecture and Design: Decorative metalwork, railings, and facades.

Conclusion

Welding and fabrication are more than just manufacturing processes — they are the foundation of industrial progress.

From precision parts to massive structures, these technologies ensure that every project stands strong, efficient, and reliable.

As the world embraces new materials and smarter production methods, welding and fabrication will remain indispensable, continuing to build the backbone of modern industry.