Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

CNC bend factory provide cnc metal tube bending service CNC bending factory made in China Our factory provide cnc tube bending service CNC bending service available CNC Bend OEM Best quality cnc metal bending

Provide OEM ODM service for metal stamping,stainless steel stamping. Our factory has over 25 years of experience in precision sheet metal stamping. High volume metal stamping with factory price. High precision metal stamping made in China.

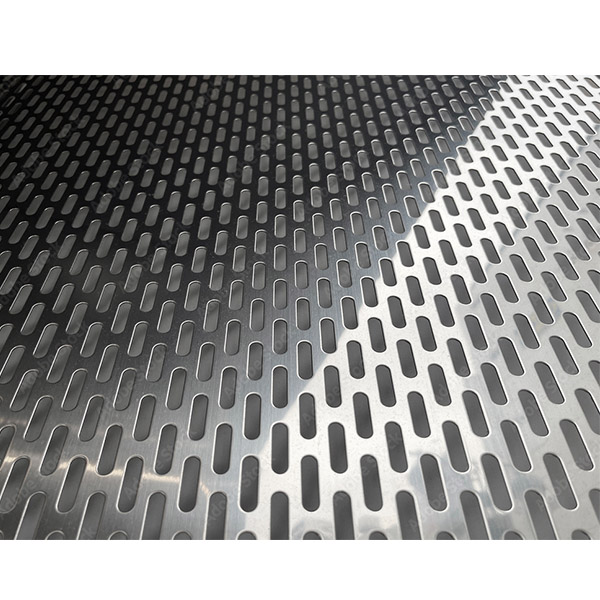

Metal Steel Plate Tag Stamping

Stamping metal steel plate tags typically involves using a specialized process to imprint information onto the surface of the metal.

Material Selection (metal tag stamping): Choose a metal that is suitable for stamping, such as stainless steel, aluminum, or brass, depending on the durability and appearance requirements.

Design Preparation: Create or obtain the design or information that needs to be stamped onto the metal tags. This could include alphanumeric characters, logos, serial numbers, or any other required information.

Stamping Equipment (metal plate stamping): Use specialized stamping equipment designed for metal tag stamping. This equipment typically includes:

- Stamping Machine: A press or a handheld stamping tool designed for metal.

- Stamping Dies(stamping steel plate): Custom dies that have the reverse of the desired design or text cut out. These are hardened steel pieces that are used to impress the design onto the metal tag.

Stamping Process:

- Alignment: Properly align the metal tag under the stamping machine or tool.

- Impression: Lower the stamp or press to apply pressure evenly across the surface of the metal tag, transferring the design onto it.

- Depth Control: Ensure the stamping depth is sufficient to create a clear, readable impression without damaging the integrity of the tag.

Finishing: After stamping, tags may undergo additional processes depending on the desired finish:

- Cleaning: Remove any debris or markings from the stamping process.

- Coating: Apply a protective coating if necessary to enhance durability or aesthetics.

Quality Control: Inspect the stamped tags to ensure the quality of the impressions meets the required standards. This may involve checking for clarity, depth, and accuracy of the stamped information.

Metal plate stamping is a manufacturing process used to shape or cut metal plates into specific forms using a stamping press. The process typically involves the application of high pressure to a sheet of metal, which is placed between a die and a punch. The press then forces the metal into the die to create the desired shape. This process is widely used in industries like automotive, aerospace, and electronics for producing parts with high precision and consistent quality.

Advantages of Metal Stamping:

Precision: Stamping can produce highly accurate and repeatable parts.

Speed: High-speed presses can produce thousands of parts per hour, making it ideal for mass production.

Cost-Effective: Once the dies are made, it becomes very economical for large quantities.

Versatility: Stamping can be used on a wide range of materials, including steel, aluminum, copper, and brass.

For businesses or individuals looking to stamp metal steel plate tags, it’s often advisable to work with a specialized manufacturer or supplier who has the equipment and expertise to ensure high-quality, consistent results.