Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

CNC bend factory provide cnc metal tube bending service CNC bending factory made in China Our factory provide cnc tube bending service CNC bending service available CNC Bend OEM Best quality cnc metal bending

Provide OEM ODM service for metal stamping,stainless steel stamping. Our factory has over 25 years of experience in precision sheet metal stamping. High volume metal stamping with factory price. High precision metal stamping made in China.

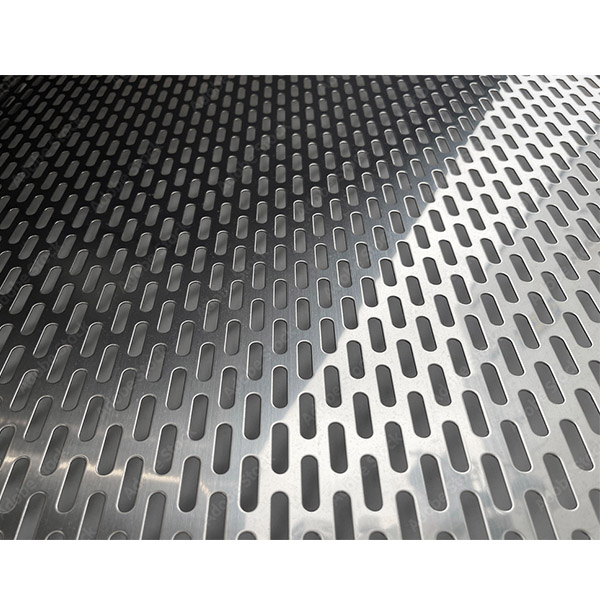

Metalwork And Stamping Punching

Stamping and punching are terms often used in manufacturing and crafting, and they refer to processes for shaping or modifying materials.

Stamping : Stamping involves pressing a metal sheet between two dies to cut or shape it. This can include creating specific shapes, cutting out parts, or embossing designs. It's commonly used in automotive, aerospace, and electronics industries.

Progressive Stamping: Uses a series of dies to perform different operations in a single machine cycle. It’s efficient for high-volume production.

Deep Drawing: Involves drawing a metal sheet into a deeper shape, like a cup, using a die and a punch.

Metal punching is a specific type of stamping where holes or cutouts are created in the metal sheet. A punch and die are used to shear out the desired shapes from the metal. The main components are:

Punch: The tool that presses into the metal to create a hole or cutout.

Die: The tool that supports the metal sheet and receives the punched material.

Material: The type of metal (e.g., steel, aluminum) affects how the stamping or punching is done.

Thickness: The thickness of the metal sheet impacts the choice of tools and process parameters.

Tolerances: Precision is crucial for many applications, especially in high-tech or automotive industries.

Stamping in metalworking is a manufacturing process where flat metal sheets are shaped or cut into desired shapes through the use of a stamping press. This process is widely used for high-volume production of parts and components, such as automotive body panels, household appliances, and even electronics.

Types of Dies in Metal Stamping:

Single Operation Dies: These dies perform one stamping process at a time, like cutting or bending.

Progressive Dies: These dies perform multiple stamping operations in a single press, gradually shaping the metal as it moves through different stations within the die.

Compound Dies: These dies perform several operations simultaneously, cutting, bending, or shaping in one press cycle.

Advantages of Metal Stamping:

High Production Speed: Stamping allows for rapid production of large quantities of parts, making it cost-effective for mass production.

Precision: Stamping can produce parts with high precision, often within a few thousandths of an inch.

Material Efficiency: It generates minimal waste because the metal is precisely cut to the required shape.

Strength: Parts produced by stamping can be very strong, depending on the material used.

Materials Commonly Used in Stamping:

Steel (both carbon and stainless)

Aluminum

Brass

Copper

Titanium (for specialized applications)

Both processes are valuable in manufacturing for their ability to produce high volumes of parts quickly and with consistent quality.

Are you working with a stamping project, or just curious about how it works?