Wholesale Cheap Replacement Aftermarket Car Parts

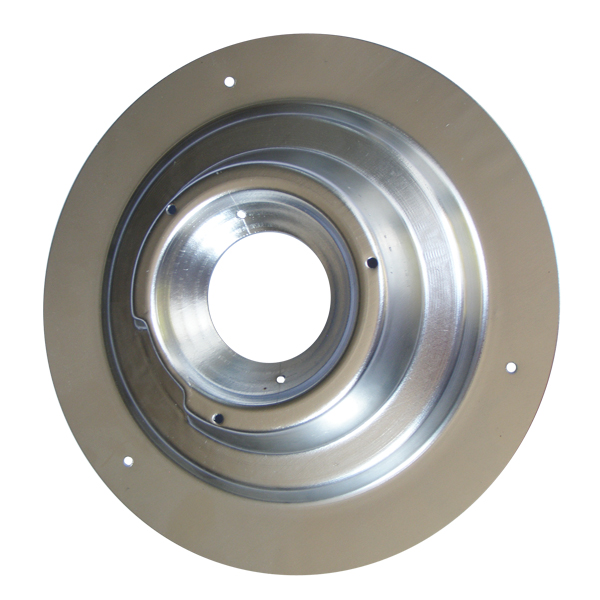

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

CNC bend factory provide cnc metal tube bending service CNC bending factory made in China Our factory provide cnc tube bending service CNC bending service available CNC Bend OEM Best quality cnc metal bending

Provide OEM ODM service for metal stamping,stainless steel stamping. Our factory has over 25 years of experience in precision sheet metal stamping. High volume metal stamping with factory price. High precision metal stamping made in China.

Stainless Steel Sheet Metal Stamping

Stainless steel stamping is a manufacturing process where stainless steel sheets or coils are shaped and cut into specific forms using a stamping press. This process is often used to create parts and components for various industries, including automotive, aerospace, electronics, and construction.

Material Preparation: Stainless steel sheets or coils are cleaned and prepared for stamping.

Tooling: Stamping dies or molds are designed and created. These tools will have the specific shapes and patterns needed for the final product.

Stamping Process: The prepared stainless steel is fed into a stamping press where it’s subjected to high pressure. The press uses the dies to cut, form, or shape the metal into the desired parts.

Stainless Steel Stamping refers to the process of forming flat stainless steel sheets into specific shapes using a stamping press. It's commonly used in manufacturing components for industries like automotive, medical, aerospace, and consumer products due to stainless steel's durability, corrosion resistance, and aesthetic appeal.

1. Process Overview

Blanking: Cutting raw material into flat shapes.

Forming: Bending, punching, deep drawing, or coining the sheet into the desired form.

Finishing: Polishing, deburring, or coating for functionality and appearance.

2. Common Grades Used

304: Most common, good corrosion resistance and formability.

316: Higher corrosion resistance (marine and medical use).

410/430: Ferritic stainless steels, more affordable, used when corrosion resistance isn't critical.

3. Tooling

Dies must be hardened and wear-resistant due to the strength of stainless steel.

Progressive dies are often used for high-volume parts.

4. Challenges

Work hardening: Stainless steel gets harder as it's formed.

Springback: Stainless steel may "spring" back slightly after bending, requiring compensations in die design.

Tool wear: High durability of stainless steel increases tool wear.

5. Applications

Kitchen appliances

Medical instruments

Automotive trim and components

Aerospace brackets and housings

Electronics housings and EMI shielding

Advantages of Stamping Stainless Steel

High production speed (especially with progressive dies)

Consistent, repeatable parts

Cost-effective for large runs

Supports complex geometries

Stainless steel is favored in stamping for its durability, corrosion resistance, and aesthetic appeal. The process allows for precise and efficient production of complex shapes and high-volume manufacturing runs.